William Rowland atomises first 100% revert blend of metal powder for Additive Manufacturing

July 8, 2020

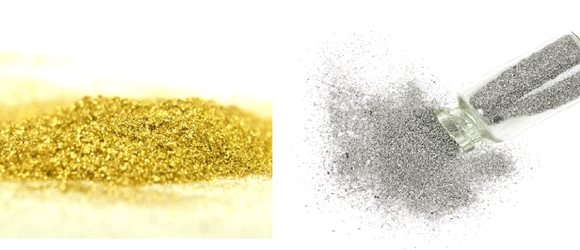

William Rowland, Barnsley, South Yorkshire, UK, reports the successful atomisation of its first batch of metal powder from a specially selected 100% revert blend, for use in both laser and electron beam Additive Manufacturing.

Thanks to its access to a vast range of high-purity metals and alloys, it was able to select a feedstock with the right chemistry and compact density to trial the melt using a toll atomising partner. The material (F75), a cobalt-chrome alloy typically used in the medical industry, was successfully atomised to 15–53 µm and 53–106 µm, suitable for Electron Beam Powder Bed Fusion (PBF-EB) and Laser Beam Powder Bed Fusion (PBF-LB).

The company has been supplying metal powder for over forty years, and whilst much of its offering has been elemental powders, it has recently begun to address the challenges facing the metal Additive Manufacturing industry.

The company stated that it accepted the challenge to atomise this first 100% revert powder blend because it was of the view that the AM industry will face the same structural input cost challenges as more established wrought methods did in order to become commercially viable and upscale. This will, it reports, involve to some degree a move away from virgin materials and pre-alloyed bar stock, which have typically been the raw materials of choice in the developmental phases of AM.

The material from atomised batch was supplied to the customer, but a small batch of samples was retained by William Rowland for interested parties including current and prospective customers.