Wayland Additive’s NeuBeam process to open up further industrial applications

April 28, 2020

Wayland Additive, Huddersfield, UK, has announced the development of a new metal Additive Manufacturing method it calls the NeuBeam® process. Said to be an entirely new Powder Bed Fusion (PBF) process, it is claimed that NeuBeam offers the best of both laser and electron beam PBF systems, opening up Additive Manufacturing to a wider range of industrial applications.

Will Richardson, CEO of Wayland, explained that the new technique is an eBeam PBF process that effectively neutralises the charge accumulation generated by the electron beam. This offers greater flexibility than L-PBF while overcoming any stability issues associated with eBeam PBF. In addition, this means that the NeuBeam process enables metallurgical requirements to be tailored to application requirements rather than to maintain the print process within the narrow bounds permitted by the process.

“At Wayland Additive, we have been working on the development of an entirely new PBF process for metal Additive Manufacturing that minimises the existing limitations that current users have to work around. When considering the existing two PBF technologies, NeuBeam offers a new way, a third way,” stated Richardson.

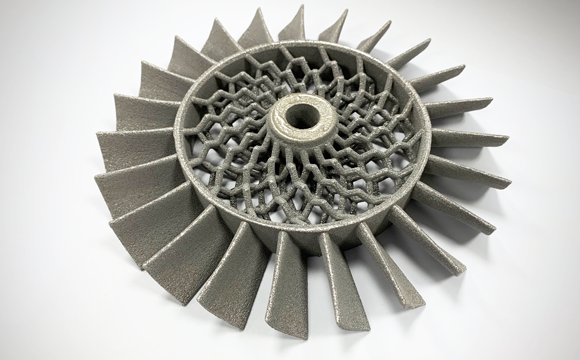

Although EBM and NeuBeam are both PBF processes, using an electron beam as the heat source to melt the metal powder, it is stated that EBM and NeuBeam are fundamentally different. Unlike the traditional eBeam PBF process, the charging issues that can make EBM unstable have been fully neutralised with NeuBeam using core physics principles developed in the demanding semi-conductor industry. Moreover, NeuBeam is a hot part process rather than a hot bed process. This efficiently creates parts that are free of residual stresses because the high temperatures are only applied to the part and not the bed, ensuring free-flowing powder post-build (no sinter cake) and stress-free parts with reduced energy consumption.

Furthermore, the process is reported to overcome many of the limitations for additively manufacturing large components – no residual thermal stresses, no gas cross-flow, and a much simplified powder removal process than existing eBeam systems.

The NeuBeam process is capable of producing fully dense parts in a wide range of materials, many of which are not compatible with traditional EBM or L-PBF processes such as refractory metals and highly reflective alloys.

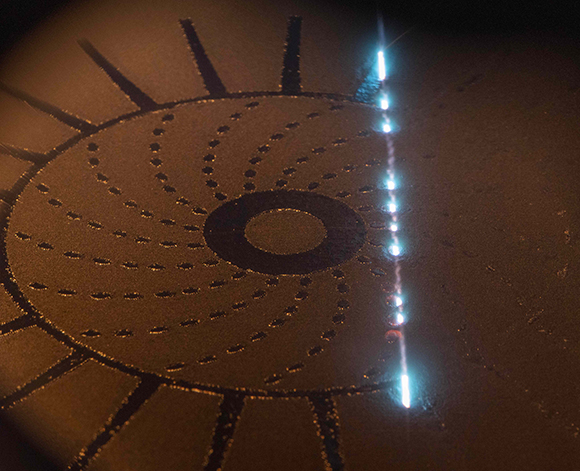

NeuBeam also offers built-in real-time in-process monitoring, allowing for rapid material development or tuning of microstructures by adapting the solidification during manufacture. With NeuBeam the process temperature is not constrained by sintering the powder bed, allowing the process temperature to be optimised to the material microstructure and/or the application.

The level of in-process monitoring is achieved through a combination of advanced technologies, including structured light scanning, electron imaging and high speed infra-red cameras. Each of these different monitoring approaches are calibrated to the same reference points in the machine, with managed adjustments, to ensure optimum results and output. Being a true thermal process, everything in the build chamber is able to be monitored, and it is possible to see the true temperature of the whole powder bed in-process as a build takes place. The thermal history of the material being processed can also be seen, as can the topography of the surface so that defects can be detected, and reported, as they occur.