Vertex to offer contract manufacturing with Xerox ElemX liquid metal

February 15, 2022

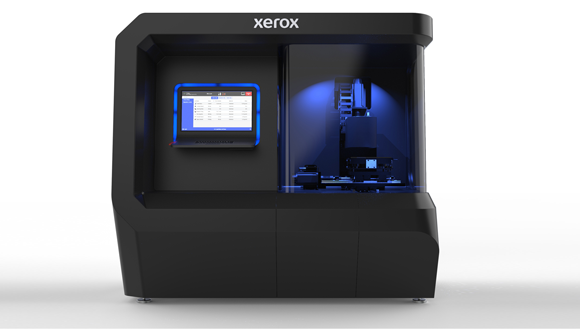

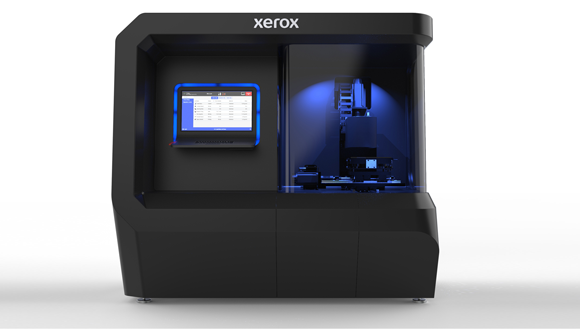

Vertex Manufacturing, a PrinterPrezz company, based in Cincinnati, Ohio, USA, is to install a new Xerox® ElemX™ Additive Manufacturing machine at its Cincinnati facility. The agreement with Xerox Elem Additive Solutions, part of Xerox, headquartered in Norwalk, Connecticut, USA, will allow Vertex to offer contract manufacturing services with Xerox’s novel liquid metal AM technology.

Xerox’s liquid metal process uses aluminium wire and requires no special facility modifications for operation. Unlike alternative AM technologies, there are no metal powders with ElemX and no need for PPE or other considerable safety measures. Engineered to bring simplicity to the supply chain process, ElemX is said to be the ideal option for spares, repairs and low-volume production parts.

By adding the ElemX to its existing fleet of advanced manufacturing technologies, Vertex states that it will become a valuable addition to the Xerox Elem Additive Solutions Manufacturing Partner Network.

“Our business is committed to delivering products and services that meet or exceed our customers’ quality and schedule requirements,” stated Tim Warden, vice president of sales & marketing at Vertex. “We decided to partner with Xerox because the ElemX technology gives us an added advantage to build parts faster and more reliably for our customers.”

The ElemX AM machine was commercially introduced in February 2021, and over the past year, Elem Additive Solutions has grown significantly, including opening an Additive Manufacturing Center of Excellence in Cary, North Carolina. The contract manufacturing agreement with Vertex is said to be another important milestone for Xerox.

Tali Rosman, Elem Additive General Manager and VP at Xerox, commented, “The relationship with Vertex enables our Elem Additive business to scale and support our customers better than before. Between the two organisations, there are decades of experience in advanced manufacturing, so we are thrilled to push the limits of this technology together.”

Rosman continued, “ElemX takes all the benefits of 3D printing and makes it easier than ever before for manufacturers to use metal Additive Manufacturing. This is the next step in our journey, and we plan to continue advancing our vision for more resilient supply chains in 2022 working with partners like Vertex.”