Safran unveils Add+ engine demonstrator featuring almost 30% AM parts

June 21, 2019

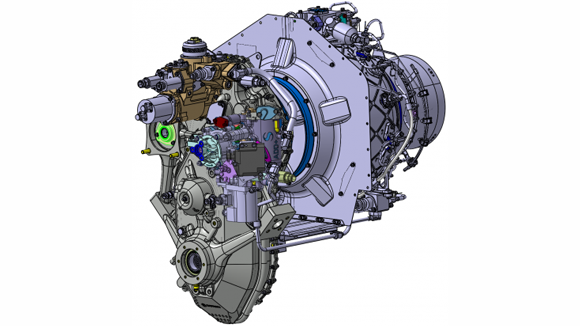

The Add+ engine demonstrator is intended to drive increased adoption of AM across Safran group (Courtesy Safran Group)

During the Paris Air Show, June 17–20, 2019, Safran Group introduced the Add+, a demonstrator engine in which almost 30% of components are additively manufactured. Produced as the result of a partnership between several Safran companies, Add+ was reportedly developed to drive increased adoption of Additive Manufacturing across the group for production engines.

Etienne Hesse, R&T Project Manager and Add+ programme coordinator at Safran Helicopter Engines, stated, “Add+ brings together 3D printing expertise from across the Safran group. We started work on an existing engine model and redesigned almost 30% of its components using Additive Manufacturing techniques, with a view to integrating those components into serial production units. When we start ground runs, we will evaluate behaviour of these new parts in operation.”

Development of the Add+, which is based on the Arrius helicopter engine, began in early 2018 and assembly is now in progress, with ground-run testing reportedly set for next Autumn. Parts were produced using Laser Powder Bed Fusion (L-PBF), drawing on the group’s metal Additive Manufacturing capabilities at its facilities in Bordes, Saclay and Corbeil, France.