Researchers report powder-size driven melt pool engineering approach for microstructure control

April 19, 2024

Researchers at Nanyang Technological University and the National University of Singapore have published a paper investigating microstructure control in the metal Additive Manufacturing process. The paper, titled “Powder-size driven facile microstructure control in powder-fusion metal Additive Manufacturing processes,” appears in the journal Nature and explains how the ability to control microstructural evolution during part fabrication can be beneficial in producing complex shapes with predictable mechanical properties.

Moreover, the ability to tailor the microstructure should be adaptable to various AM techniques, state the authors. This is particularly demanded for stainless steel 316 L due to its widespread applications for general purposes in many industry sectors under harsh and corrosive environments.

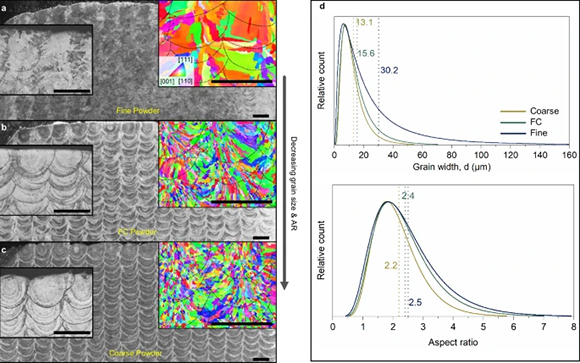

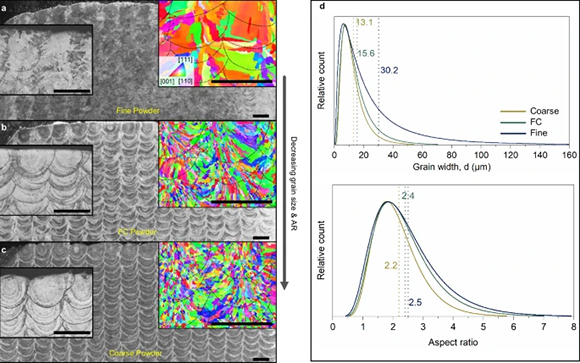

The paper reports a powder-size-driven melt pool engineering approach that demonstrates facile and large-scale control in the grain morphology by triggering a counterintuitive response of powder size to the additively manufactured 316 L stainless steel microstructure. The researchers obtained coarse-grained (>100 μm) or near-monocrystalline microstructure using fine powders and near-equiaxed, fine-grained (<10 μm) microstructure using coarse powders.

This approach reportedly shows adaptability to Directed Energy Deposition and Powder Bed Fusion with no added cost, where the particle-size dependent powder-flow preheating effects and powder-bed thermophysical properties drive the microstructural variations.

The work looks to present a pathway for leveraging feedstock particle size distribution towards more controllable, cost-effective, and sustainable metal Additive Manufacturing.

To read the full article, click here.

Download Metal AM magazine