Rivelin Robotics reports progress of Innovate UK’s Project CAMPFIRE for automated post processing

May 2, 2024

As the lead partner of an Innovate UK funded project, Rivelin Robotics, based in Sheffield, UK, is working to deliver a complete digital post-processing solution for the automated finishing of flight parts, orthopaedic implants and gas turbine components produced using metal Additive Manufacturing.

Designated Project CAMPFIRE (Certified Additive Manufactured Parts Finished with Intelligent Robotics Engine), Rivelin is collaborating with five partners. Three are specific to post-processing applications for regulated industries using metal Additive Manufacturing — Attenborough Medical, GKN Aerospace and Materials Solutions (a Siemens Energy Business) — whilst partners Yaskawa EU and Saint-Gobain Abrasives are delivering key hardware technologies.

Borne of experience as an engineer tasked with removing metal supports from additively manufactured parts and achieving various levels of surface finish, Rivelin’s CEO, Robert Bush, established the company in 2018 to develop a real and repeatable solution to the problems he faced, knowing that he was not alone.

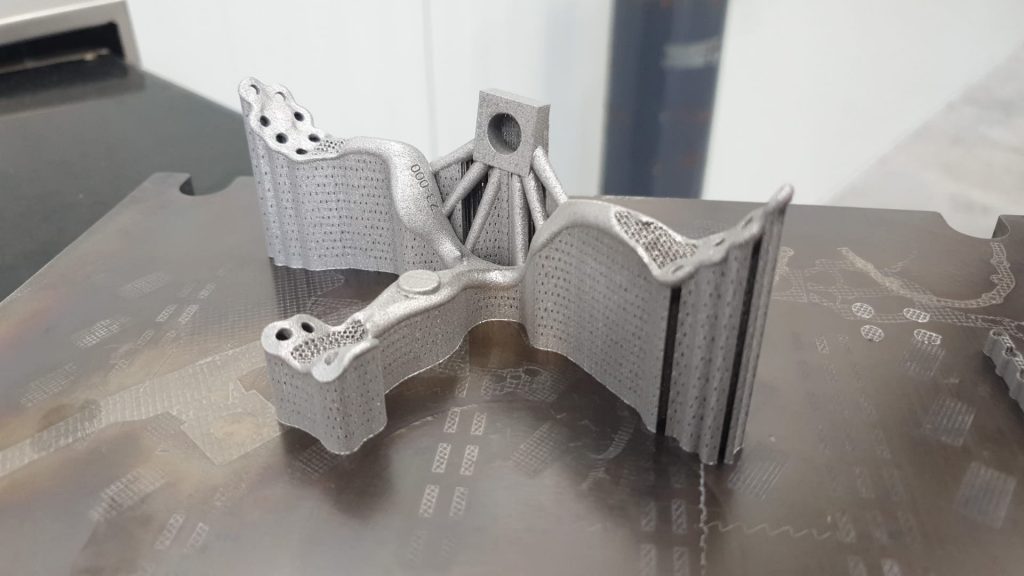

The challenges with post-processing metal parts are many, not least the labour-intensive, time-consuming, filthy and sometimes dangerous activities involved in removing metal supports with hand tools, explains Rivelin. Moreover, there are additional operational considerations of this manual approach that also pose challenges, such as repeatability, quality control, long lead times and high costs. These considerations are fundamental for regulated industries that have to adhere to stringent compliance standards.

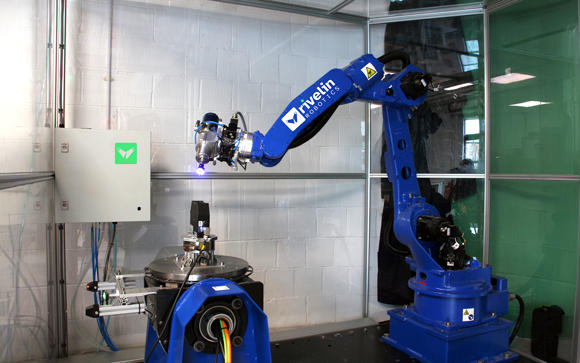

Since its founding, the Rivelin team has developed and commercialised a solution – delivered to the market in the form of its Netshape Robots – that can provide truly autonomous post processing capabilities.

Three companies that are utilising metal AM processes for production applications at increasing scale from three different regulated industries have been keen to work with Rivelin to test and implement the NetShape robots for their own applications. Project CAMPFIRE is providing a creative and collaborative way from this to move forward. Attenborough, GKN and Materials Solutions are all companies that have been dealing with the challenges of post-processing metal AM parts for many years.

GKN Aerospace

GKN Aerospace is a leading Tier 1 supplier to the aerospace industries, with customers including Airbus, Rolls Royce and GE. GKN Aerospace has been maturing metal AM for over a decade, working to develop and exploit the technology on both civil and military aerospace programmes, and has achieved a number of milestones in this process.

GKN’s current focus is to utilise its additive fabrication technology to offer reliable and sustainable ready-to-use alternatives to castings and forgings within its engines business. GKN has its AM centre of excellence within its Bristol based Global Technology Centre, where it houses a range of AM machines, ancillary equipment and a team of over 15+ research engineers and material scientists.

GKN has engaged in Innovate UK supported R&D projects ATI DAM & ATI Horizon in recent years, working successfully with the wider UK eco-system to drive the development of UK-wide AM capabilities. Project CAMPFIRE extends this expertise further down the AM process chain. The post processing phase remains a barrier on a number of fronts, specifically productivity and reliable quality assurance for higher volumes of parts.

Brad Hughes, Principal Research Engineer – Additive Manufacturing at GKN Aerospace, commented, “Powder Bed Additive Manufacturing is a core part of GKN Aerospace’s long-term strategy as we look to diversify our material supply chain, enabling us to grow our business and better serve our customers. Whilst AM has the potential to deliver multiple benefits in aerospace, from product performance to sustainability improvements, there are clear barriers to its adoption.”

“Currently, AM products are most commonly finished via manual operations, with support material removed by hand in labour-intensive processes causing bottlenecks in our manufacturing processes. Manual support removal is typically not accurate enough and not repeatable, varying widely from technician to technician. In some cases, the support removal process can result in part defects, with non-conforming parts therefore needing rework, or sometimes even a complete rebuild. With the continued industrialisation of Additive Manufacturing meaning more parts being produced year on year, it is challenging to scale manual support removal into a quality assured economical process,” he added.

“Through the CAMPFIRE programme, GKN Aerospace are collaborating with Rivelin Robotics to explore the use of robotic systems to automate the process of removing support material from complex Aerospace products. The Rivelin technology offers many attractive features to aerospace end users: the opportunity to remove human interactions, improve repeatability and productivity. Working with Rivelin, we will assess the performance of their current system on site at GKN Aerospace’s Global Technology Centre in Bristol UK, and through feedback we will specify upgrades and modifications that can be incorporated into future systems. This will ensure the technology has a route to scalable adoption in the aerospace sector, meeting the needs of end-users. The upgrades will be validated by the consortium, through a joint technology demonstrator enabling us to quantify the benefits of the technology against the rudimentary manual removal methods,” concluded Hughes.

Materials Solutions

At Materials Solutions, a Siemens Energy business, the mission is to enable customers to meet the growing global demand for energy while transitioning to a more sustainable world. The company’s production facility in Worcester is a digital manufacturing facility with other similar facilities in Germany, Sweden and the United States.

The use of metal AM as a production method for industrial gas turbine components is increasing rapidly, according to Trevor Illston, Chief Manufacturing Engineer at Materials Solutions. He commented, “The major advantage of using AM is the ability to manufacture highly complex, optimised geometries that can increase the performance of the gas turbines. A good example of this is for stage 1 turbine vanes where the ability to design and manufacture highly complex internal cooling schemes has enabled vanes to be introduced with enhanced operational life, along with a significant reduction in cooling air requirements and allowed the use of more cost-competitive turbine alloys.”

Illston explained, “The current support removal method that we employ involves a complex process chain utilising EDM to remove the bulk of the support from the leading edge followed by manual support removal using pneumatic tools and manual surface dressing. A rework loop is often required to ensure that the surface profile tolerance and surface quality required is achieved for the final components. This is both time consuming and not particularly efficient; it has long been the major bottleneck in the overall AM process. The target of our involvement in Project CAMPFIRE is to utilise the Rivelin Netshape Robot to reduce the number of operations in the process chain and demonstrate an improvement in the vane leading edge quality to routinely meet the requirements without any additional rework on the surface to increase productivity.”

Another key goal of the project for Materials Solutions is achieving certification for energy parts within demanding requirements of the energy sector.

Attenborough Dental and Medical

The Attenborough dental business founded the UK’s first digital production centre in April 2000 and operates a full suite of production equipment, including twenty-two one-tonne milling machines, ten large-format Additive Manufacturing machines and two further Laser Beam Powder Bed Fusion (PBF-LB) AM machines serving the UK, Europe and the Middle East with over 260 satellite scanning centres.

Ed Attenborough, the company’s CEO and a vocal proponent of metal Additive Manufacturing for the production of parts, commented, “Using metal AM for the production of patient specific implants in dental and medical field is not new, we’ve been researching and subsequently doing it for years. There are many advantages for using AM to manufacture the implants. Patient-specific implant devices are all unique to the patient, and each one is specially design based on the patient’s individual anatomy and clinical requirement. AM enables this type of personalisation and mass customisation of complex implants as well as reduced material waste and freedom of design. Thus, using AM for manufacturing the individual implants is the best option for us.

“The post-processing phase of metal AM implants is a major bottleneck in our overall process. As our business has grown and volumes continue to increase, finding a solution to overcoming this bottleneck is imperative. Apart from the time it takes for each part with increasing volumes, other challenges include the fact that different medical implant sizes can vary and the parts themselves tend to be small, delicate and fragile. It is not uncommon for parts to break during support removal or warp due to external forces applied to the part during the manual removal process. This affects both our overall productivity and consistency and these are the issues we are looking to resolve. Being part of Project CAMPFIRE is a no-brainer and potentially a game-changer for us. We working collaboratively within this project because we need a full digital post processing solution,” Attenborough shared.

Rivelin Robotics has developed and supplies the digital capabilities for this solution, but the full package also requires advanced hardware. While Rivelin’s Netshape capabilities are hardware agnostic, the company has partnered with advanced hardware suppliers for Project CAMPFIRE that enable the full solution to be delivered.

Yaskawa EU

As an industrial drive and robot arm manufacturer, Yaskawa is a key partner for Rivelin and can also bring system integration capabilities; Yaskawa is delivering robot and positioner cell solutions directly to Rivelin. This allows Rivelin to focus on the integration and implementation of their sensors and processes to bring dexterity, versatility, and ease of operation as a complete customer-focused solution for their customers.

Jonny Grey, Sales Director at Yaskawa UK said, “Yaskawa is passionate about pushing the benefits of robotic automation to manufacturers. Through Rivelin, we see the potential for robotic post processing of AM parts to be increasingly adopted across many industries, even those that are highly regulated. Yaskawa has the robotic products and manufacturing capabilities needed to support these solutions as demonstrated by the cross-collaboration of Project CAMPFIRE. It’s an exciting partnership and one that presents Yaskawa with a unique value generation opportunity leveraging both our robotic products and operational strengths.”

Saint-Gobain Abrasives

Saint-Gobain has over 100 years of experience as a global leader in grinding technology and tool solutions. Now, however, the company is fully aware of the transition to automation and the commercial potential that it offers.

Gabriele De Blasio is Robotics Manager for Abrasive Applications EMEA, stated, “Automation is absolutely the key for post-processing. We have several customers worldwide working in the field of turbine blades processing, and traditionally all of those have been finished manually. That’s changing now and we are excited to be involved in this project as we witness the transition to fully automated post processing.”

Robert Bush, CEO of Rivelin Robotics, added, “Leading Project CAMPFIRE is a significant milestone for Rivelin Robotics. While we have been delivering and installing Netshape Robots to key customers since last year, this project is a brilliant way to demonstrate the capabilities of Netshape across industries and applications. Users of metal AM for production are unanimous in their demand for an automated solution for support removal and finishing. Regardless of the parts and how or where they will be used, the shared pain in getting those parts from the AM machine to the point of use is prevalent and engenders collaboration to solve the issues. This is exactly what Project CAMPFIRE aims to do and in the coming weeks and months we look forward to sharing deeper insights and key results.”

www.saint-gobain-abrasives.com

Download Metal AM magazine