AML3D expands presence in Australian Defence sector with aerospace contract

May 2, 2024

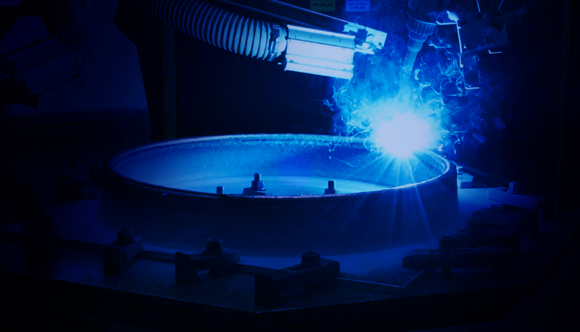

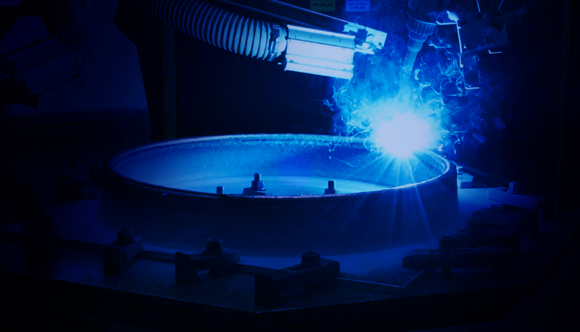

AML3D Limited, headquartered in Edinburgh, Australia, has signed a contract with Toolcraft Australia to supply a six-part nozzle assembly for an Australian Government Defence Science and Technology Group (DSTG) project. The AUS $350,000 contract follows the successful delivery of a four-stage nozzle assembly that demonstrated AML3D’s Wire Arc Additive Manufacturing (WAAM) technology and delivered superior components with significantly shorter lead times compared to traditional manufacturing.

The new contract expands the scope of work previously undertaken for the DSTG project to include two additional stages of an Aluminium ER5183 nozzle assembly, which is expected to weigh approximately 1230 kg and have a length of over 3.6 metres. The expanded scope follows confirmation of the superior operational performance of the previously manufactured AML3D’s additively manufactured four-stage nozzle assembly components. Manufacturing of the six-part nozzle assembly is expected to commence immediately, with the first two stages to be delivered during the current financial year and the remaining four stages in FY25.

While AML3D is experiencing strong demand within the US defence sector for its Wire Arc Additive Manufacturing technology, with close to AUS $12 million of contracts delivered through AML3D’s USS ‘Scale up’ strategy in CY2023, expanding into additional significant defence markets is a key strategic objective. This six-part nozzle assembly contract, in support of the DSTG’s aerospace project, is aligned with this medium-term growth objective.

AML3D CEO Sean Ebert stated, “We are extremely pleased to continue to expand on our previous work supporting the DSTG. It is a strong endorsement of AML3D’s WAM technology for defence applications to have the scope of this A$0.35 million contract expanded to two additional nozzle segments that had previously been traditionally manufactured. AML3D’s ability to use our proprietary WAM technology to produce higher quality components, with significantly faster turnaround times compared to traditional manufacturing and with less waste, allows us to play an increasingly important role in defence supply chains.

“Alongside our extremely successful US ‘Scale up’ strategy, which has seen AML3D secure close to A$12 million in US defence contracts in support of the US Navy’s submarine industrial base in 2023, we are also committed to developing our presence in additional globally significant defence markets. WAM printing multistage nozzle assemblies for this DSTG project not only expands our presence in the Australian Defence sector but also into aerospace defence an area we have identified as being a strategically important growth driver over the medium term,” Ebert added.

Download Metal AM magazine