Nvision and Watershed Idea Foundry debut titanium AM anterior cervical plate

January 12, 2022

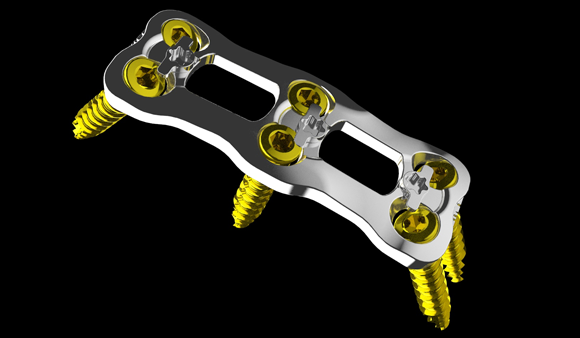

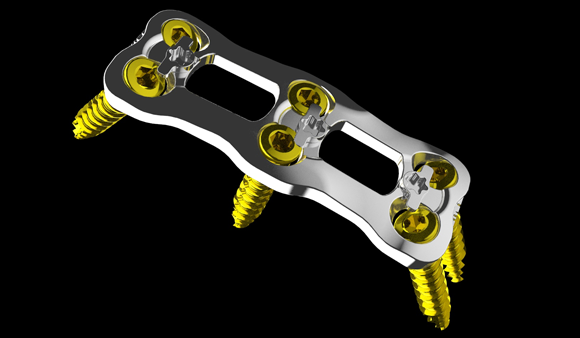

Nvision Biomedical Technologies, San Antonio, Texas, USA, and Watershed Idea Foundry, Carslbad, California, have received FDA clearance for what is said to be the first-ever completely additively manufactured titanium anterior cervical plate: the Quantum Titanium Cervical Plate System. Recently cleared, the Quantum system is expected to lead the way in design freedoms that positively impact patient care.

The Quantum system offers multiple specialised features, including a nested assembly in which the screw-locking cover is additively manufactured as a single unit inside the anterior cervical plate, and dual-plate finishes with a textured posterior surface and smooth, polished anterior surface. Enhanced screw holes accommodate 30º of cephalad/caudal angulation, which allows the surgeon to use a shorter plate. Additionally, the Quantum system incorporates Structural Encoding® capabilities to address FDA Unique Device Identification (UDI) requirements.

“It has been incredibly exciting for us to realise new product enhancements made possible by Additive Manufacturing,” stated Nick Cordaro, CEO of Watershed Idea Foundry. “Combining multiple components into single nested 3D printed assemblies is one example of such an advancement, which can provide supply chain cost and timeline advantages while reducing patient risks of component disassembly. Nvision’s willingness to champion Additive Manufacturing innovation into a commercial product made for an ideal technology transfer scenario.”

Tom Zink, Nvision’s Senior Vice President of Product Development, added, “By Additive Manufacturing the Quantum system, we leveraged design options that were not available with machined plates. The active locking system is integrally printed within the plates, and therefore never assembled, which means the locks cannot become unassembled in the surgical field. The posterior side of the Quantum plates present texture to allow for osteointegration and is designed to allow the plate to absorb load that with traditional plates is fully on the screws. With the hyper angulation of the screw holes design, the surgeon has the option to place the screws as far away from adjacent levels as possible.”

As sister organisations within the Fountainhead Investment Partners portfolio, Nvision and Watershed have previously collaborated on other innovative projects, such as Structural Encoding and additively manufactured wedges and interference screws.