Nidec to showcase its DED Additive Manufacturing machines to North American customers

May 10, 2023

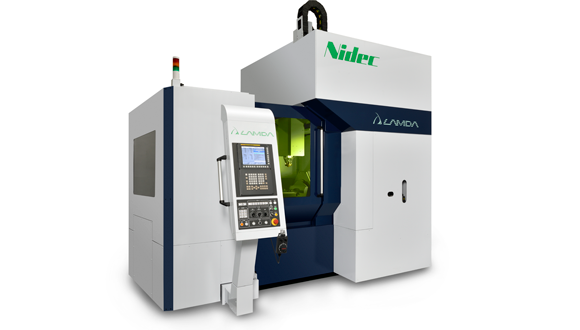

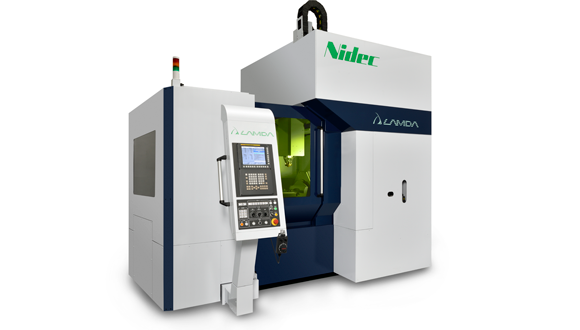

Nidec Machine Tool America, Wixom, Michigan, USA, the US division of Japan’s Nidec Corporation headquartered in Kyoto, has begun installation of a LAMDA500 powder-based Directed Energy Deposition (DED) Additive Manufacturing machine at its US facility. The new machine will be used to demonstrate the LAMDA500’s capabilities, as well as offering customers prototypes and test parts starting in June 2023.

“The LAMDA500 installation at our Wixom, MI, facility emphasises our full commitment to the North American market,” stated Hirohisa Kuramoto, Global AM Marketing Director. “We will partner with customers to make samples and test parts as well as perform process development in Michigan.”

The Nidec LAMDA500 laser DED machine has a maximum build envelope of 500 x 500 x 500 mm and is available with 1, 2, 4 or 6 kW lasers.

Using a Nidec-exclusive proprietary nozzle design with local shielding of the melt pool, the LAMDA series Additive Manufacturing machines do not require an environmental chamber for inert gas. The nozzle, designed with the use of computational fluid dynamics (CFD), provides a large shielded area for reactive materials such as titanium and aluminium.

The LAMDA observes the molten state of the metal with a camera and stores the images as traceability data for the build process, while its high-speed image processing algorithm instantly reports changes in feature values to the laser oscillator and mechanical equipment to modify the laser irradiation energy, build speed, etc, to stabilise build quality.

Nidec Corporation was founded in Kyoto, Japan, in 1973, as a manufacturer of and distributor of electric motors. The company’s first prototype high-accuracy DED Additive Manufacturing machine was produced in 2014, with its large-scale (2,000 x 1,500 x 1,600 mm) machine released in 2020.

www.nidec-machinetoolamerica.com

www.nidec.com/en/nidec-machinetool

Download Metal AM magazine