MolyWorks adds 3D Systems’ DMP Flex 350 Additive Manufacturing machine

May 2, 2023

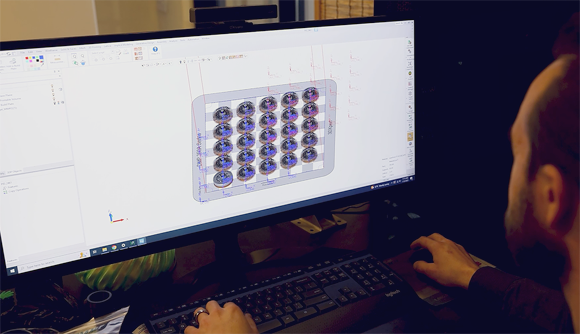

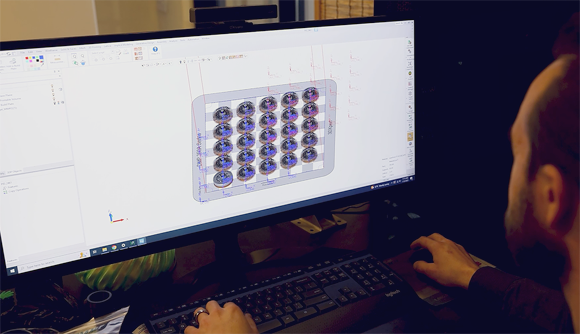

3D Systems, Rock Hill, South Carolina, USA, has announced that MolyWorks Materials Corporation, located in Los Gatos, California, USA, has integrated the DMP Flex 350 into its metal Additive Manufacturing workflow. This in-house production capability has now seen MolyWorks grow its customer base, including the work the company is conducting alongside the United States Air Force to evaluate additively manufactured flight-critical parts.

MolyWorks reportedly chose 3D Systems’ DMP Flex 350 Laser Beam Powder Bed Fusion (PBF-LB) machine due to its advanced vacuum chamber architecture which is critical when manufacturing parts from titanium. The vacuum chamber maintains a low oxygen environment (<25 ppm) which reduces argon gas consumption.

“The high-value applications we are addressing with Additive Manufacturing require us to have a metal 3D printing solution that can maintain a very low internal oxygen level,” stated Devin Morrow, director of AM, MolyWorks. “The DMP Flex 350, with its unique vacuum chamber, performs in a different class than competitive machines. The vacuum architecture reduces O2 levels to less than 25 ppm and delivers better chemistry control in finished parts and high levels of powder reuse. Being able to seamlessly transition from design and optimisation in 3DXpert to production with the DMP Flex 350 has really helped us streamline our process.”

The DMP Flex 350 includes Oqton’s 3DXpert software which supports the full Additive Manufacturing workflow, from design to post-processing, to quickly and efficiently transition from a 3D model to AM parts. This single software solution for modeling, simulation, and manufacturing is said to eliminate the need for multiple software packages.

It was stated that MolyWorks is also taking advantage of the DMP Flex 350’s optional removable print module (RPM). Being able to swap out the RPM allows the company to perform a quick cleanout and get the machine back up and running with another material in a short amount of time.

Chris Eonta, founder, MolyWorks concluded, “For rapid design or product iteration, 3D Systems’ DMP Flex 350 is unmatched. Having this industry-leading solution in our facility is expanding our vision of what can be 3D printed in our processes. We’re very impressed by the quality of the landing gear components we’re producing with this printer that will be tested for airworthiness, and are looking forward to the additional applications we will address.”

Download Metal AM magazine