MKS announces Ophir BeamPeek Software for laser beam analysis

June 30, 2023

MKS Instruments Inc., based in Andover, Massachusetts, USA, has announced the release of Ophir® BeamPeek™ software for field technicians. The laser beam analysis software is designed to provide fast, accurate, real-time measurements of lasers in Additive Manufacturing chambers.

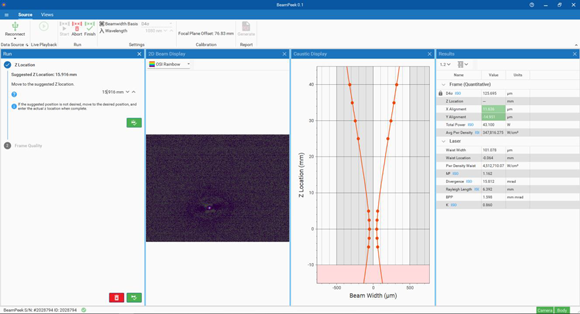

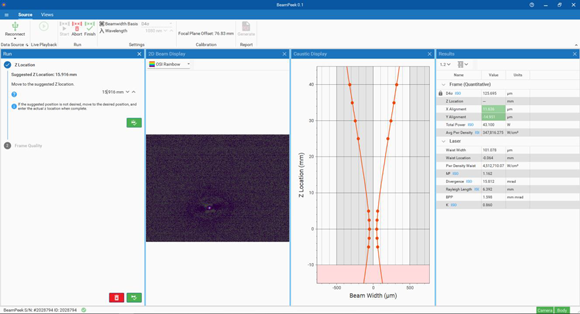

Specifically for the needs of field maintenance, the system reportedly analyses the most critical beam parameters for process optimisation, including waist width and location, power density, M2, beam parameter product (BPP), ellipticity and Rayleigh length. Technicians are then provided with a comprehensive view of the beam’s shape, size, and intensity distribution, facilitating rapid identification of any irregularities or deviations.

BeamPeek Software features 2D beam display, caustic display, and stacked 3D beam display to represent and visualise beam measurement results; the interface can also be customised to specific user needs. Additionally, the results display panel represents key laser parameters: beam width, ellipticity, Z location, X alignment, Y alignment, total power, and average power density for a given frame, as well as waist width, waist location, power density at waist, M2, BPP, and K for the caustic measurements.

For more detailed results and analyses, technicians can load the results file from BeamPeek Software into Ophir BeamGage Professional software for full post-processing capabilities. BeamGage software reportedly includes all the calculations needed to make accurate, ISO approved laser beam measurements, including power and spot diameter, power density, spot position, and more. The software provides advanced image processing features, NIST-traceable power measurements, trend charting, data logging, pass/fail production testing, and multilingual support.

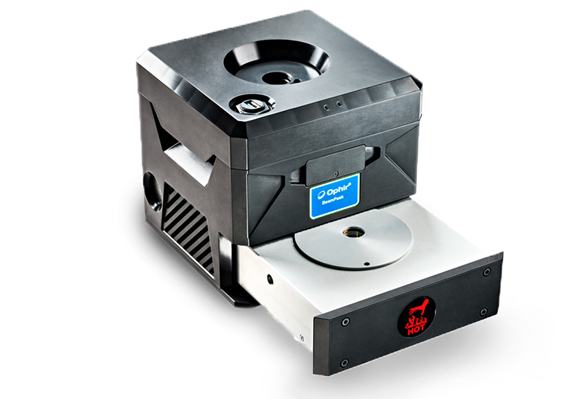

BeamPeek Software works with Ophir BeamPeek, a laser beam analysis and power measurement system for Additive Manufacturing. The system provides beam profiling, focal spot analysis, and power measurement in just three seconds. There is reportedly no need for water or fan cooling as the system includes a replaceable passive cooling beam dump tray that eliminates downtime between measurement sessions.

The BeamPeek system is said to be ideal for field service testing of Additive Manufacturing chamber powder beds. It is able to withstand chamber conditions, including the presence of metal powder residuals and when cooling agents or airflow connection points are not available. The BeamPeek system is supported by a range of Ophir software options: BeamPeek Software, StarLab, BeamPeek Tool, and, for more complex analyses, BeamGage Professional.

“Additive Manufacturing chambers present a challenging environment for high power laser-based systems and the field team responsible for optimising performance,” said Reuven Silverman, General Manager, Ophir Photonics. “BeamPeek Software allows users to obtain critical beam measurements in the shortest time possible with little or no user intervention. If desired, they can also enter their own custom measurement locations with ease. The end result is clear and concise data that technicians can trust, as it is ISO 11145 and ISO 11146 compliant.”

Download Metal AM magazine