Metallic3D introduces new bound metal paste Additive Manufacturing machine

February 11, 2020

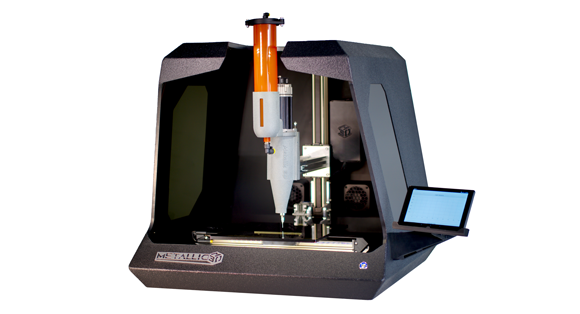

Metallic3D, based in Stuart, Florida, USA, has added a new metal Additive Manufacturing machine, the M3D300. Utilising the company’s bound metal paste deposition technology, the M3D300 is reported to offer a safe, easy to use system capable of manufacturing components in a wide range of metals.

The bound metal paste process is said to be suitable for any office or workshop environment, with no fumes or odors created in the M3D300 machine. Due to the use of a solvent-based binder in the feedstock, the company states that most of the binder evaporates during the build. Any residual binder is then removed during the sintering stage, rather than an additional de-binding stage, which Metallic3D says makes its AM process faster from initial design to fully finished part.

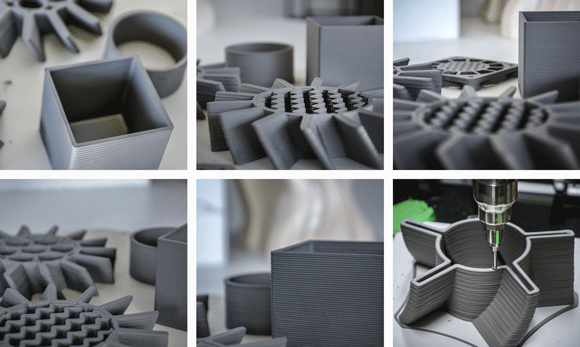

“Additive Manufacturing has now for some time been the solution of choice when producing highly diverse parts,” states owner of the company, Dan Defelici. “3D printing enables the emergence of radical product innovation through function-oriented design properties. Paired with the outstanding material properties of high-performance ceramics and advanced metal powders, industries and research teams can now explore entirely new areas of applications.”

By building the complete system in-house Metallic3D states it can significantly lower the barrier of entry into Additive Manufacturing. “Our new desktop printer is up to 10x less expensive than alternative metal Additive Manufacturing technologies and up to 100x less than traditional fabrication technologies like machining or casting. This gives the owner of a Metallic3D printer a higher ROI, less time making parts and fewer worries over quality,” added Defelici.