Eplus3D qualifies Constellium’s Aheadd CP1 alloy for its AM machines

October 4, 2022

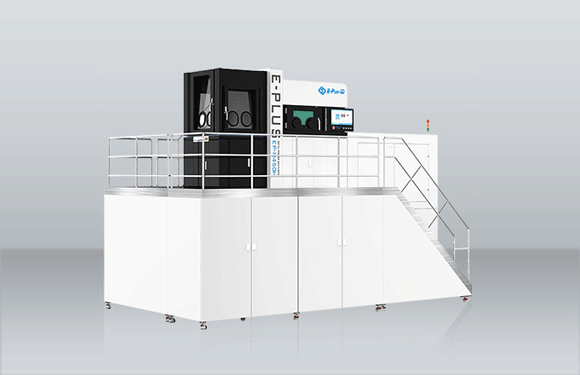

Eplus3D, headquartered in Hanzhou, China, has qualified the Aheadd®CP1 aluminium alloy from Constellium, headquartered in Paris, France, for use on the company’s Laser Beam Powder Bed Fusion (PBF-LB) Additive Manufacturing machines.

Constellium designed the Aheadd CP1 solution specifically for the PBF-LB process and is reported to offer excellent strength and thermal conductivity, suitable for applications in the automotive, semiconductor, aerospace and spare parts industries.

Aheadd’s silicon-free chemistry facilitates high-quality anodisation for additively manufactured components, making it an excellent choice for highly challenging applications in industries such as semiconductor equipment manufacturing.

Eplus3D states that its large-scale and multi-laser metal AM machines have achieved impressive build quality of average density of 99.93% with a robust process window. The high ductility of Aheadd CP1 in the as-built state will enable Eplus3D customers to produce large-scale components with minimal geometrical distortion. In addition to its metal AM machines, Eplus3D also provides consulting, application development, consulting services and customer training.

Both Constellium and Eplus3D believe that the AM development of Aheadd CP1 alloy will enable aluminium components users to design new applications and lower the cost of production and increase productivity for better ROI.

For more background on Constellium’s Aheadd CP1 aluminium alloy, read our article Constellium Aheadd® CP1 alloy: Breakthrough productivity in PBF-LB Additive Manufacturing in the Spring 2022 issue of Metal AM.