Desktop Metal releases Live Suite end-to-end software package

March 7, 2023

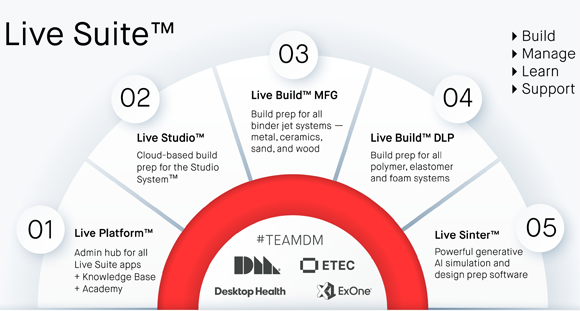

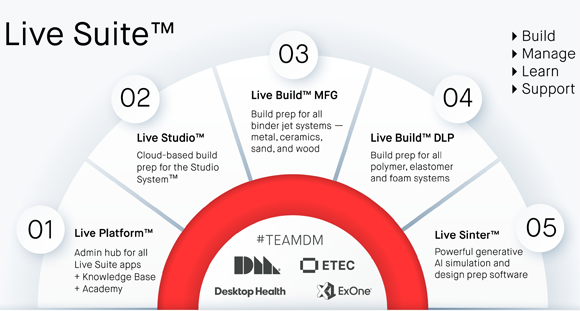

Desktop Metal, Boston, Massachusetts, USA, has launched Live Suite™, a package of software applications bringing new functionality for users of the company’s Additive Manufacturing 2.0 machines across its Desktop Metal, Desktop Health, ETEC and ExOne brands.

Building on the company’s Live Sinter simulation software, Live Suite enables users to additively manufacture their digital designs easily and accurately in metal, polymer, and ceramic parts. Live Sinter uses an advanced multi-physics approach based on GPUs to simulate the end-to-end Additive Manufacturing and sintering process, generating new design shapes that will deliver the desired final part within tight tolerances. Furthermore, Live Sinter applies state of the art machine learning to calibrate this simulation process to match real-world results for Binder Jetting.

“AM 2.0 is a digital manufacturing process that is ultimately powered by software, and we believe Live Suite offers the most intuitive and powerful AM software on the market,” stated Ric Fulop, Founder and CEO of Desktop Metal. “Live Suite is the culmination of six years of development by our talented global software team to make AM technology easy to use and ensure it delivers the highest quality results with the most intelligent approaches. As a result, the high level of success that users of our Binder Jet and DLP technology experience today is simply unmatched.”

Desktop Metal confirmed that Live Suite will come standard with most new hardware this year, and is intended to eliminate the need for users to purchase other AM software programs to use their equipment.

“Our strategy remains focused on keeping digital manufacturing accessible, so our users have the tools they want and don’t pay for expensive features they don’t need,” Fulop added.

A cloud-based hub

Live Platform is the new cloud-based hub for all Live Suite applications and services. Organised into four content categories — build, manage, learn, and support — the hub enables users to manage their entire workflow in one location with two-factor authentication security.

Live Platform is also the new central administration hub for Live Suite, with the ability to provision and manage Desktop Metal AM systems and users, as well as access firmware updates, knowledge, and technical support. A new Business Units feature allows larger companies with multiple users and departments to easily manage AM machine permissions and controls for groups.

Customers will also be able to use Live Platform to add on a wide range of application-specific options, such as part serialisation or optimised build instructions for specific parts ranging from dentures to valves. Examples of special add-on features include Autopilot, which automates build preparation for both dental and additional part-specific applications, and Live Monitor, which will soon be available to remotely view jobs as they progress through machines and ancillary equipment.

Live Suite contains the following:

- Live Sinter

- Live Build MFG, which replaces Desktop Metal’s Fabricate MFG application, will. support build preparation for all Binder Jetting of metal, wood, ceramic, and sand designs. Customers currently using ExOne X-Prep or other similar tools will be phased into Live Build MFG over the next year

- Live Build DLP

- Live Studio, which also replaces Fabricate, and supports slicing and build preparations for Desktop Metal’s Bound Metal Deposition machines, including the Studio System 2

Download Metal AM magazine