Canadian FabLab installs Rapidia metal Additive Manufacturing system

February 8, 2020

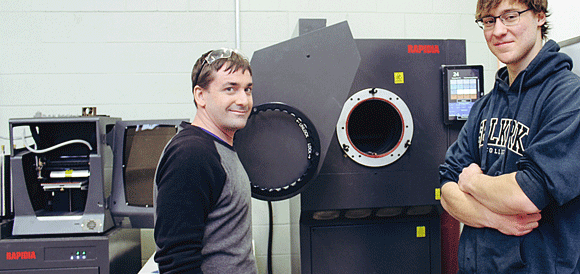

The Kootenay Association for Science and Technology (KAST) based in Trail, British Columbia, Canada, has installed a Rapidia metal Additive Manufacturing system, at its MIDAS Lab. The Metallurgical Industrial Development Acceleration and Studies – or MIDAS Lab – is reported to be the first rurally located FabLab (fabrication laboratory) in Canada to install a metal AM system.

The MIDAS Lab provides access to the equipment needed for digital fabrication and rapid prototyping, as well as project work areas, a research and development lab, a metal shop, a woodshop, a computer lab and a training centre.

“Metal printing is a game-changer for fabricating parts and prototypes,” stated Cam Whitehead, Executive Director of KAST. “Lower costs and increased speed to produce prototypes means faster innovation and more competitiveness. This all means more jobs and wealth for the region. Our services are available to commercial members, unlike most universities—these machines are so new and expensive that previous focus has been on research and not necessarily business needs.”

“MIDAS Lab is unique in Canada and has been since it opened its doors in 2016,” added Whitehead. “We’re thrilled that it’s received countrywide recognition and we’re using some of the lessons learned to help other startup fabrication labs and innovation centres across B.C.”

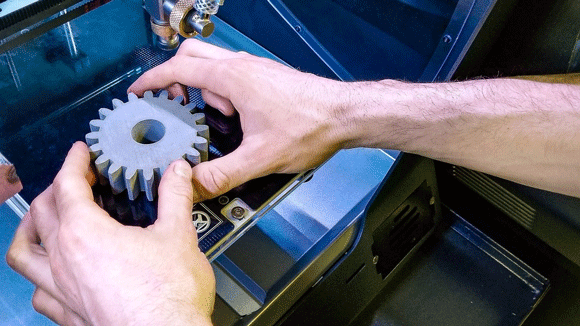

The Rapidia system uses a water-based metal paste which eliminates the debinding step, enabling the two-stage Rapidia process to produce most parts in under twenty-four hours. The system is also believed to cut Additive Manufacturing time further by avoiding the need to produce a metal base plate or most metal supports. It is capable of building a range of materials including stainless steel, Inconel, tool steel, ceramics and titanium.

“While there are printers that can do what the Rapidia can do, we chose this one because of its safe operation, the speed at which you can operate and create the designs and parts that our industry partners and Selkirk College needs,” explained Jason Taylor, Instructor & Applied Researcher at Selkirk College.

KAST partner, Selkirk College plans to launch Digital Fabrication & Design, a two-year diploma programme that trains graduates for advanced manufacturing, in September 2020. Daryl Jolly, School of the Arts chair, stated that the Rapidia system will be an exciting new educational tool students will be able to utilise. “As we launch this new programme, it’s exciting to again see that Selkirk College students will be trained on and have access to world-class equipment. We expect our graduates will be well-positioned to support continued economic growth in our region, bringing value to industry and innovation,” Jolly commented.