Authentise and nebumind awarded EU grant for collaboration

May 13, 2021

Authentise, a developer of data-driven workflow tools for Additive Manufacturing founded in San Francisco, California, USA, with offices in London, UK; Kiev, Ukraine and Philadelphia, Pennsylvania, USA, and nebumind GmbH, Taufkirchen, Germany, a provider of visualisation and analytics tools for manufacturing data, have been awarded a competitive grant from the European Union to enable further collaboration between the two companies.

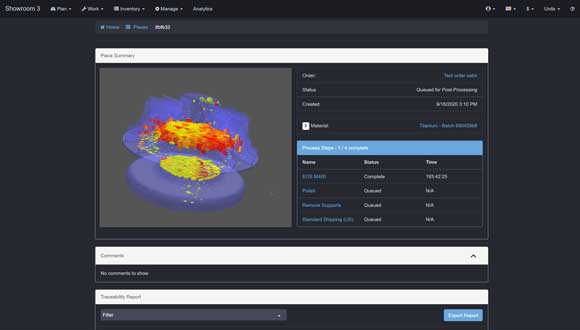

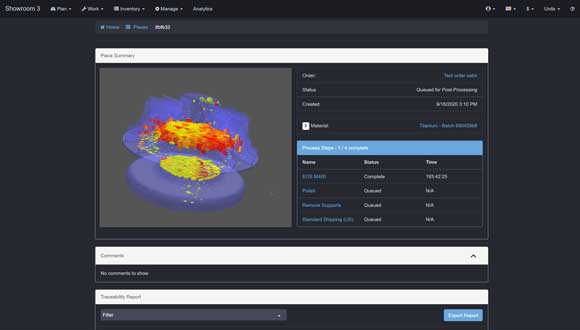

Announced in November 2020, the companies are collaborating to integrate nebumind’s ‘digital twin’ visualisations, which fuse machine parameters and sensor data with the original part geometry, with Authentise’s aMES data-driven workflow management. This reduces time to set up the visualisations by using data already present in aMES, and provides access to the digital twin from within the interfaces users already work in. This increases part-by-part analytics and thus reduces part processing time and costs. The insight generated will also contribute to automated quality reporting within aMES.

The collaboration is funded by the European Union’s Horizon 2020 research and innovation programme through Digifed, the Digital Innovation Hubs Federation For large scale adoption of digital technologies by European SMEs.

“This support is incredibly meaningful not only to our joint ability to execute as planned but to the market in general,” stated Caroline Albert, co-CEO at nebumind. “Enabling integration of digital solutions such as nebumind and Authentise in this way boosts the value to industrial customers who are already overwhelmed with a plethora of different tools and reduces the reliance on solutions sourced from single vendors. Manufacturers in general are playing catch up when it comes to digitisation and these benefits make their adoption of the digital thread more likely, and the tools more powerful thanks to a more dynamic market.”

Andre Wegner, CEO of Authentise, commented, “We’re delighted to have been selected for this highly competitive programme by the European Union. It not only speaks to the power of nebumind’s digital twin visualisation solution, but also validates the Authentise approach. Unlike many larger companies, we explicitly don’t want to build or own everything ourselves. We’d rather partner. It makes sense because there’s still a lot of work to do, and these kinds of partnerships free us up to solve other challenges. It also makes sense for customers because they save time from no longer having to interact with multiple software solutions and are guaranteed cutting edge solutions by specialisation and constant innovation. We’re delighted that the EU has recognised this and is supporting this integration.”