Austal orders largest AML3D ARCEMY Additive Manufacturing machine to date

November 21, 2023

AML3D Limited, based in Edinburgh, Australia, has announced an order for a large-scale, custom-built ARCEMY metal Additive Manufacturing machine from Austal USA Advanced Technologies. The new machine will be installed at Austal’s Advanced Technologies facility in Charlottesville, Virginia, USA.

Worth approximately AUS $2.2 million, this is the second order received from Phillips Corporation since the start of their reseller agreement in April 2023. Phillips Corporation is sourcing ARCEMY units for the US marine shipbuilding industry, including the US Navy’s supply chain and industrial base.

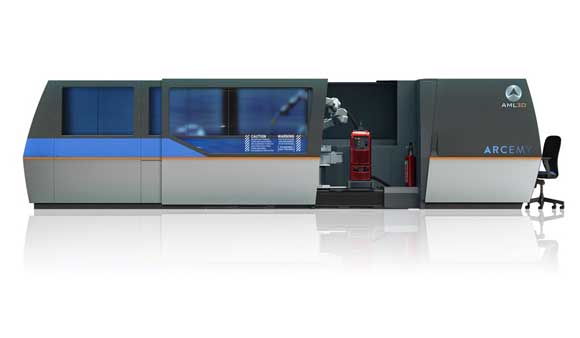

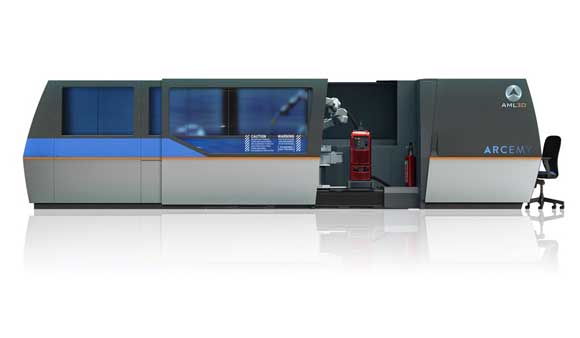

The custom-built ARCEMY unit will be based on the ARCEMY 6700 machine. Once installed, it will be the largest build to date, utilising an 11,000 kg positioner and a linear rail over 4 m, creating a build volume of approximately 35 cubic metres. The unit is expected to be completed and installed by mid-2024.

Austal USA Advanced Technologies leads a team of industry partners and operates the Navy’s Additive Manufacturing Center of Excellence in Danville, Virginia. This centre is reported to be the US Navy’s flagship for Additive Manufacturing, creating components for the construction of the next generation of ships and boats.

Austal USA is investing in future capabilities to enhance post-delivery support and sustainment services. This investment also supports multiple shipbuilders, maintenance providers, and various naval forces including the US Navy, US Coast Guard, Royal Navy, and Royal Australian Navy. This broad support extends to military ships deployed in the US and its allied fleets.

AML3D Managing Director, Sean Ebert, shared, “This second order by Philips over the past few months evidences the success of the reseller agreement with Phillips, which provides us with leverage their long-standing relationships with the US Department of Defense and their suppliers, enabling us to accelerate the development of a US ARCEMY sales pipeline to both navy and its industrial base.”

“The sheer size of the custom-built ARCEMY unit demonstrates the breadth of demand and application of our technology, and importantly reaffirms the potential to further expand our footprint within the US Government and defence supply chain,” he added.

“As momentum within AML3D’s US scale-up strategy continues to grow, we are seeing the commercial benefits. Notably this order, demonstrates strong alignment of our strategy with Austal USA Advanced Technologies efforts to revolutionise the US Navy’s supply chain through the implementation of Additive Manufacturing for castings, forgings, and fittings.”

“The US is the largest Additive Manufacturing market in the world and AML3D’s most important growth market. The company remains confident additional contracts in support of the US defence sector will be executed during the current financial year,” concluded Ebert.

Download Metal AM magazine