AML3D reports record Q4 2023 driven by momentum in the US market

January 23, 2024

AML3D Limited, headquarted in Edinburgh, Australia, has released its quarterly report for the period ended December 31, 2023. Record quarterly cash receipts were noted for the second consecutive quarter, said to reflect the strong momentum in the company’s US ‘scale up’ strategy. Orders worth over AUS $12 million were delivered in 2023.

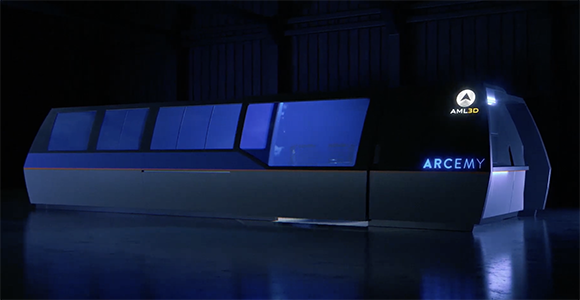

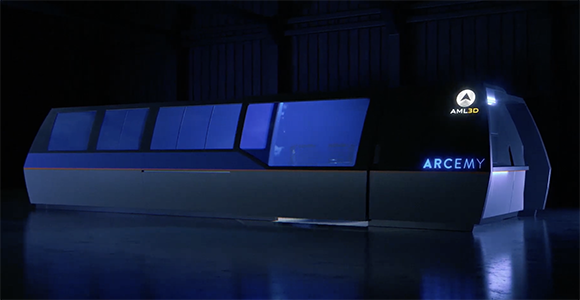

The US Department of Defence is said to be benefiting from the company’s scale up, with contract wins primarily in support of the US Navy’s submarine industrial base. The aim of the strategy is to focus on the sales of AML3D’s wire-based Directed Energy Deposition AM machines – ARCEMY – as advanced manufacturing point-of-need solutions. In addition to contracts supporting the US Navy, AML3D is developing a sales pipeline for wider applications in the US defence and federal sectors and US-based global Tier 1 Corporate customers in the marine and aerospace sectors while also pursuing opportunities in Australia and additional significant defence markets.

During the quarter, the implementation of the US scale up has resulted in a significant increase in new contracts, leading to a record quarterly customer receipt of AUS $2.46 million. As a result, the operating cash outflow for the quarter was negligible, amounting to only AUS $47,000. Financial year-to-date customers receipts are AUS $4.83 million. AML3D’s US sales pipeline is reported to remain strong and promising, with the continued expansion of existing defence and Global Tier 1 corporate relationships in Australia.

Key activities during the quarter included:

- AUS $2.5 million ARCEMY machine order from US Defence contractor – Cogitic Corporation – to support the supply of metal AM parts to the US Navy submarine industrial base.

- AUS $2.2 million order for the largest ever custom built ARCEMY machine for Austal USA’s purpose-built Advanced Manufacturing Centre in Charlottesville, Virginia

- A prototype part manufacture and testing contract to support BAE Systems Maritime Australia’s Hunter class frigate programme for the Royal Australian Navy

- Installation and commissioning of an ARCEMY X-Edition 6700 at the Oak Ridge National Laboratory in Tennessee, a major partner to the US Navy.

- Shipment of an ARCEMY X-Edition 6700 at the Oak Ridge National Laboratory in Tennessee, a major partner to the US Navy

- Shipment of an ARCEMY X-Edition 6700 machine to the US Navy’s Additive Manufacturing Center of Excellence at Danville, Virginia

- Installation and commissioning of an ARCEMY 2600 machine at US Navy submarine component partner Laser Welding Solutions

- High utilisation of Australian contract manufacturing facility to support prototype parts production

- Expansion of international protection of AML3D’s WAAM process with the granting of an Indian patent

Download Metal AM magazine