Additive Manufacturing research facility orders Quintus HIP

September 16, 2021

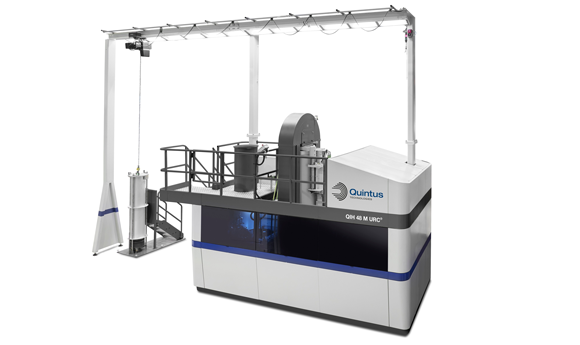

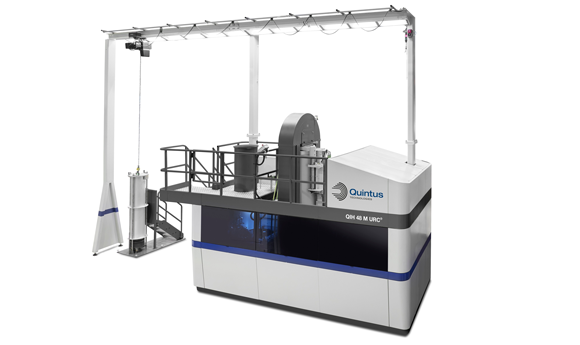

Quintus Technologies, Västerås, Sweden, reports that a Quintus QIH 48 M Hot Isostatic Press (HIP) will be installed at the additive research facility at the new Oregon Manufacturing Innovation Center Research & Development (OMIC R&D) in Scappose, Oregon, USA.

Overseen by Oregon Institute of Technology (Oregon Tech), a public polytechnic university, OMIC R&D is a collaborative effort that brings together industry and higher education with government support to conduct applied research and advanced technical training. Its mission is to increase industrial competitiveness by developing new tools and techniques to address today’s manufacturing challenges, particularly in the aerospace and defence, transportation, and metals sectors.

The Quintus QIH 48 M URC® press will allow new research into Additive Manufacturing technology and optimised material properties. The press model is equipped with Uniform Rapid Cooling (URC), the proprietary Quintus feature that combines HIP and heat treatment in a single process. Accelerated cooling under pressure is said to minimise thermal distortion and improves material properties.

“For OMIC R&D to fulfil our mission, we must have world-class cutting-edge capabilities to support our applied research & development projects. We accomplish this by partnering with some of the best companies in the world in their respective fields and identifying and utilising their unique technologies and expertise. Our solutions can be implemented by regional, national, and international partners to increase their competitiveness,” stated Craig Campbell, OMIC Executive Director.

“We chose Quintus as a partner because the company is continually innovating, and developing new processes such as High Pressure Heat Treatment, or HPHT. After evaluating the needs of the industry, we concluded that HIP and HPHT would be critical sciences in the commercialisation of Additive Manufacturing.”

Operating at a temperature of 1400°C and a pressure of up to 2070 bar, the new press will give OMIC researchers the ability to study densification of metals as well as how HPHT can modify the grain structure to enhance the mechanical properties of additively manufactured parts. The QIH 48 has a hot zone of 375 mm in diameter and1200 mm in height.

The press will be housed in OMIC’s new 2800 m2 Additive Manufacturing innovation centre in Scappoose, approximately twenty miles north of Portland. Scheduled for ground-breaking in late 2021 and occupancy in 2022, the world-class facility will be adjacent to the Portland Community College/OMIC Training Center, which serves students in machining, fabrication, and mechatronics.

Dr Mostafa Saber, Associate Professor of Manufacturing & Mechanical Engineering Technology at Oregon Tech, commented, “Today’s globally competitive manufacturing industry demands rapid innovations in advanced manufacturing technologies to produce complex, high-performance products at low cost. To conduct world-class, competitive research on new high-performance metal alloys, long-lasting tools, and rapid production of complex metal structures, especially in Additive Manufacturing, materials densification plays a pivotal role. And that is where the advanced generation of hot isostatic pressing offers the solution. We are very excited to leverage the advantageous features offered by Quintus Technologies soon at OMIC R&D.”

“We are delighted to be working with OMIC R&D as its talented researchers expand applications for high pressure and heat treatment,” added Jan Söderström, CEO of Quintus Technologies. “As the industry leader in advanced Hot Isostatic Pressing technology for over sixty years, we see the rapid emergence of HPHT as the go-to post-processing path to lean, competitive AM operations. It is deeply gratifying to support new manufacturing approaches that improve quality, lower cost, and reduce environmental impact.”