Winners of Formnext Start-up Challenge 2018 revealed

September 25, 2018

The winners of the Formnext Start-up Challenge 2018 have been revealed as 3DFortify, Aerosint, AMendate, Kumovis and Nanogrande. Now in its fourth year, the award honours companies founded within the last five years who demonstrate groundbreaking innovations in Additive Manufacturing.

The official awards ceremony will be held on the opening day of Formnext 2018, where the winners will also have the opportunity to present their technology in the Start-up Area for the duration of the show in Frankfurt, Germany, November 13–16, 2018. “The top-quality innovation demonstrated by the prize-winners underscores the great ability of Formnext to attract new start-ups from all around the world,” stated Sascha F Wenzler, Vice President for Formnext at event organiser Mesago Messe Frankfurt GmbH.

Together with other start-ups, the winners will also have the chance to present a short business pitch as part of Formnext’s new Pitchnext event. In addition to the opportunities they receive during Formnext 2018, the prize-winning companies will be offered a range of services designed to assist them in achieving further success in the development of their company, including business coaching provided by AM Ventures.

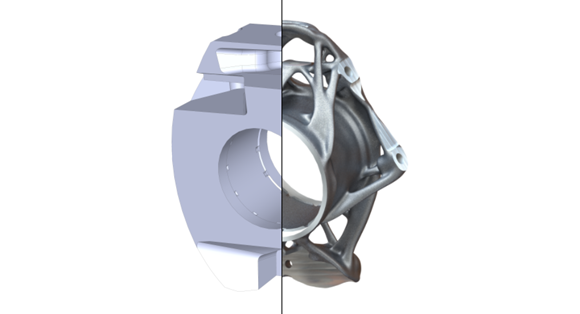

AMendate

Initial design (left) and final part design (right) enabled by AMendate (Courtesy Amendate)

AMendate, Paderborn, Germany, is the developer of software for fully-automated topology optimisation in Additive Manufacturing, resulting in organic-looking structures that offer efficient and cost-effective production.

AMendate’s technology is said to allow such structures to be generated rapidly and automatically. Its core element is an intelligent optimisation algorithm that interprets the simulation result automatically and converts it into commonly-used CAD exchange formats.

Thomas Reiher, CEO and Co-Founder of AMendate, stated, “In the field of Additive Manufacturing, Formnext has established itself as a central platform for new products and networking opportunities. As one of the winners of the Start-up Challenge, we are therefore delighted to be part of the industry’s must-attend event.”

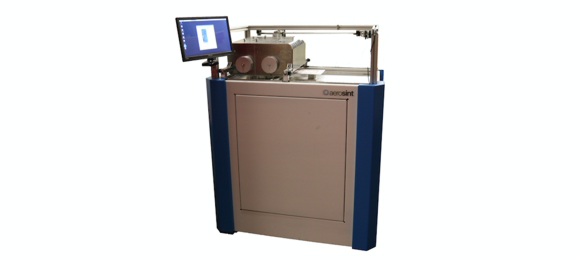

Aerosint

Aerosint’s selective powder deposition system (Courtesy Aerosint)

Aerosint, Liège, Belgium, has reportedly developed a selective powder deposition system to enable multi-material part production. In the system, multiple powder materials are deposited to form a single layer, making it possible to produce parts combining a variety of materials, including metals, polymers and ceramics, by Additive Manufacturing.

Matthias Hick, CTO Aerosint, stated, “At Aerosint we believe multi-material is the next evolution of 3D printing. Multi-material will enable parts optimisation and functionalisation like no other manufacturing technology is capable of. Replacing the traditional recoater in SLS/SLM printers with our powder deposition recoater can bring multi-material capabilities to a robust and proven technology that exists for more than thirty years.”

Nanogrande

An Additive Manufacturing system from Nanogrande (Courtesy Nanogrande)

Nanogrande, Montreal, Quebec, Canada, has developed what is claimed to be the world’s first nano-scale Additive Manufacturing process. The system can assemble highly packed multi-layers of particles as thin as 1 nm using materials such as metals, oxides, waxes and polymers.

The patented technology creates layers using fibres, flakes and unconventional particles, and is also said to be able to combine different materials to form objects with few or no supporting structures. Its high print resolution reportedly enables the Additive Manufacturing of structures in the submicron range, using particles from 1 nm to 1 mm. A build area of up to 200 mm x 200 mm is possible depending on model.

Juan Schneider, Founder and CEO of Nanogrande, stated, “It is a great privilege to introduce our technology and our products to Europe at the international exhibition on the next generation of manufacturing, the Frankfurt Formnext. […] We are convinced that Formnext is only the beginning of our adventure with Europe.”

Kumovis & 3DFortify

Also named as Start-Up Challenge winners are Kumovis, Germany, a producer of plastic medical implants by AM, and 3DFortify, which uses digital composite manufacturing for the AM of carbon fibre, fibreglass and ceramic components.