Wilting expands metal Additive Manufacturing capabilities with three 3D Systems DMP Flex 350s

March 14, 2024

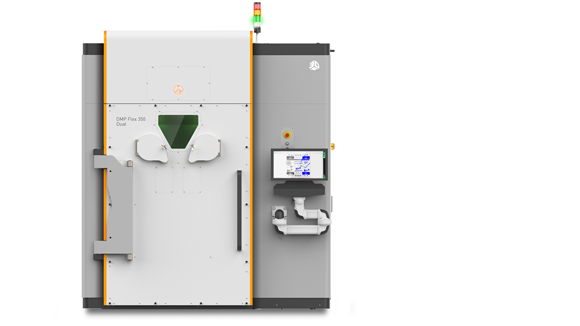

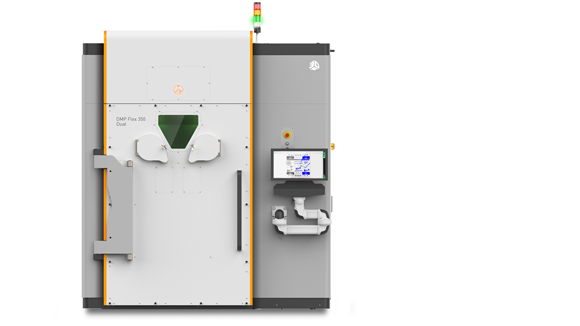

3D Systems Corporation, Rock Hill, South Carolina, USA, has announced that Wilting, an industrial machining and metal Additive Manufacturing service provider based in Eindhoven, the Netherlands, has installed two single-laser DMP Flex 350 and one DMP Flex 350 Dual metal Laser Beam Powder Bed Fusion (PBF-LB) Additive Manufacturing machines at its facility.

Wilting has experienced significant growth in its business and these new AM machines are intended to help address both the increased production capacity and broader materials portfolio required by its customers. The installation of these three DMP Flex 350 systems, alongside the two that are already in use, will enable Wilting to dedicate AM machines to specific materials such as titanium and stainless steel for the 24/7 production of highly precise end-use parts.

3D Systems’ DMP Flex 350 platform is designed for flexible application use from application development to serial production. The quick swap build modules and fast powder recycling help accelerate production and a central server manages build jobs, materials, settings, and maintenance to facilitate the 24/7 productivity Wilting requires to meet customer demand. Due to the unique vacuum chamber concept of the DMP Flex 350 AM machines, argon gas consumption is heavily reduced while delivering high oxygen purity (<25 ppm) resulting in strong parts of high chemical purity. The AM machine also includes Oqton’s 3DXpert software which supports every step of the Additive Manufacturing workflow from design to post-processing.

Wilting began as a precision machining company that was helping a large manufacturer of semiconductor capital equipment produce complex metal parts to improve system imaging accuracy and productivity. In 2012, Wilting began working with 3D Systems’ Application Innovation Group (AIG) to accelerate the adoption of advanced metal Additive Manufacturing capabilities and expertise in its facility in Eindhoven, the Netherlands. Through this collaboration, Wilting built up its expertise in metal Additive Manufacturing, post-machining, and post-processing. Using the AIG’s technology transfer process, 3D Systems engineers shared knowledge and provided training to the Wilting team to streamline and accelerate its transition to AM and safeguard its investment.

As a result, Wilting produces optimised components designed for higher performance in semiconductor capital equipment and the analytics and mobility industries and is leveraging this expertise and its additional DMP Flex 350 systems to expand into new markets and applications. To accommodate this growth and provide room for future expansion, Wilting is in the process of moving into a new 183,000 sq. ft. (17,000 m2) facility that is planned to be fully operational by mid-2024.

“We place our customers and their applications at the centre of each engagement,” said Raph Alink, account & business development manager, 3D Systems. “3D Systems pioneered the use of Additive Manufacturing to deliver precise, reliable parts for semiconductor applications. In the early days of our relationship with Wilting, it was rewarding to share the application expertise our AIG had built from more than a decade working with semiconductor capital equipment manufacturers to scale their use of Additive Manufacturing. As an industry leader, the team at Wilting quickly realised AM’s advantages. It’s a big step for a company to bring AM in-house, and Wilting has already mastered the technology and is now transferring that into volume production for its customers. I look forward to seeing how our collaboration will continue to unfold, and the potential that AM will unlock for Wilting and its growth.”

Download Metal AM magazine