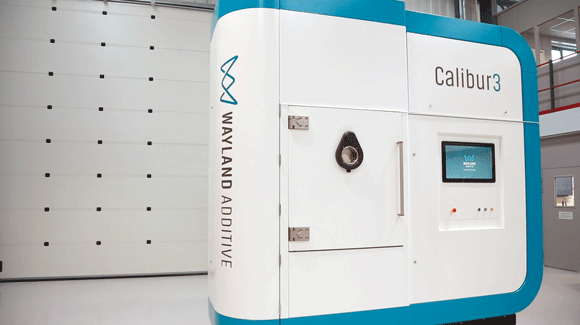

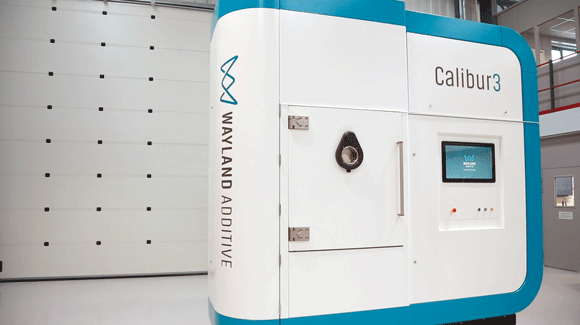

Wayland Additive will showcase Calibur3 at Formnext 2021

September 17, 2021

Wayland Additive, Huddersfield, UK, has announced that it will be exhibiting its Calibur3 metal Additive Manufacturing machine at Formnext 2021, which is scheduled to take place in Frankfurt, Germany, 16-19 November.

Following on from the machine’s launch in March of this year, Formnext represents the first opportunity for a much broader audience to get to see Calibur3 in person and to get a much deeper understanding of what that Calibur3 offers, specifically in regards to the NeuBeam metal AM process.

The NeuBeam process is intended to provides manufacturers with access to a genuine metal AM production alternative, delivering on the advantages of metal Electron Beam Powder Bed Fusion (PBF-EB) technology, whilst overcoming the issues that have traditionally hindered wider adoption.

At Formnext, Wayland will be highlighting the three core principles of NeuBeam:

- Stability: The most fundamental issue with PBF-EB technology has always been the unstable nature of the processes; Wayland believes NeuBeam has categorically resolved this. Its team comprises decades of experience with PBF-EB R&D and implementation in the semi-conductor industry, which it believes has allowed them to address and solve the charging issues that have, until now, restricted PBF-EB processes, with the fully neutralised NeuBeam process.

- Flexibility: The other key feature of NeuBeam is that it is a hot part process rather than a hot powder bed process, meaning Calibur3 is intended to produce parts free of residual stresses because the high temperatures are only applied to the part, allowing free-flowing powder post-build (no sinter cake) and stress-free parts with reduced energy consumption. This makes the process more flexible in terms of part geometries and cost efficient, because heat treatments and other post-processing steps are dramatically reduced.

- Metallurgy: Workarounds for traditional PBF-EB processes have been developed by the AM industry, but these can lead to downstream complexities, including time consuming and expensive part removal and post-processing. These compromises also severely limit the materials that can be used with this technology. Neubeam is material and can potentially run a much wider palette of metal materials, including refractory metals.

A number of the Wayland Additive team will be available on stand B139 in Hall 12 to meet visitors, introduce them to Calibur3 – which will be on the show floor – and discuss any metal AM application requirements. Those scheduling an itinerary can pre-book a meeting with a Wayland executive online.