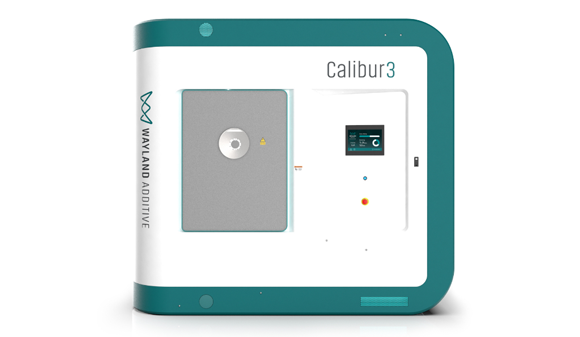

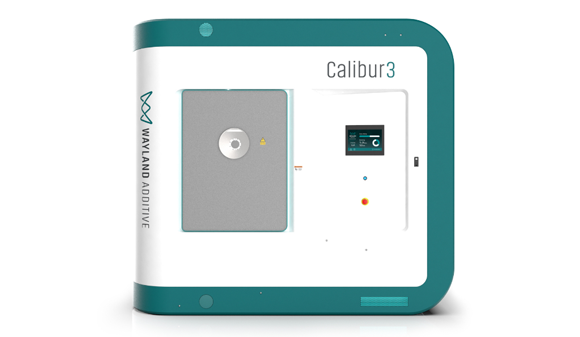

Wayland Additive to launch its NeuBeam metal AM machine Calibur 3 in January 2021

August 20, 2020

Wayland Additive, Huddersfield, UK, reports that it will commercially launch Calibur 3, its first NeuBeam® process metal Additive Manufacturing on January 27, 2021, and expects to start shipping later that year.

Developed in house, the NeuBeam metal AM process is said to be an entirely new Powder Bed Fusion (PBF) process, claiming to providethe best of both laser and electron beam PBF systems.

Although EBM and NeuBeam are both PBF processes, using an electron beam as the heat source to melt the metal powder, it is stated that two processes are fundamentally different. Unlike the traditional electron beam PBF process, the charging issues that can make EBM unstable have been fully neutralised with NeuBeam using core physics principles developed in the demanding semi-conductor industry.

Moreover, NeuBeam is a hot part process rather than a hot bed process. This i said to create parts that are free of residual stresses, because the high temperatures are only applied to the part and not the bed, ensuring free-flowing powder post-build (no sinter cake) and stress-free parts with reduced energy consumption.

The NeuBeam process is capable of producing fully dense parts in a wide range of materials, many of which are not compatible with traditional electron or laser beam processes, such as refractory metals and highly reflective alloys.

Designed specifically for production applications, the Calibur 3 incorporates fully embedded in-process monitoring capabilities that can provide full oversight during every build, ensuring full traceability for every part.

Peter Hansford, Director of Business Development at Wayland Additive, commented, “We are very happy to confirm the launch date for the Calibur 3 On 27th January next year we will be unveiling the full specs of the machine to our early adopters and partners as well as to the press at a dedicated event.”

“Currently the plan is to bring people in to see it in action for themselves if we are able to with COVID-19 restrictions, but we will also be live-streaming the event for interested parties that may not be able to attend. 2020 has been an unprecedented year in many ways and the global pandemic has caused a great deal of disruption and uncertainty,” Hansford continued.

“At Wayland, however, we have been able to navigate through these difficulties and keep our focus on the development of our system. Talking to industrial users of metal AM throughout, it is clear that despite the disruptions, many companies are still making medium and long-term plans, and we look forward to serving them with our ground-breaking technology.”

Will Richardson, CEO at Wayland Additive, stated, “Save the date in your diary now. We are in the process of curating an impressive in-person and on-line event which will be of huge interest to industrial sectors that use or are planning to use metal AM for production applications. January 27th 2021, will be a pivotal day for Wayland, but also a pivotal day for industry as they get a first clear view of the opportunities that exist through the use of our NeuBeam technology.”