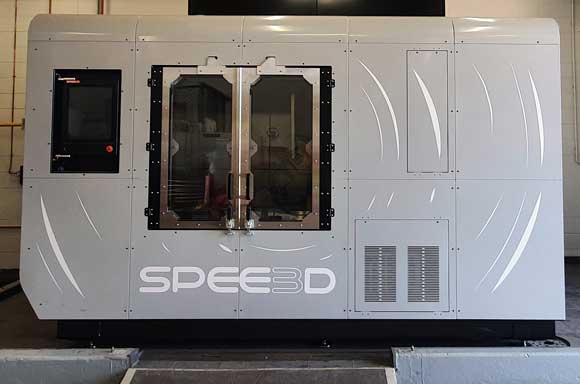

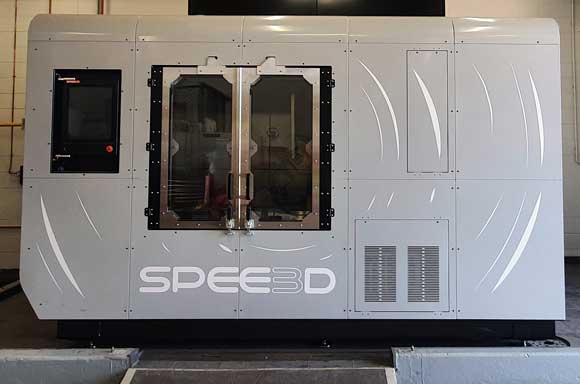

WarpSPEE3D machine installed at Royal Australian Navy port

November 20, 2020

SPEE3D, headquartered in Melbourne, Australia, reports that its large-format metal Additive Manufacturing machine, WarpSPEE3D, has been installed by the Royal Australian Navy’s Fleet Support Unit (FSU) at HMAS Coonawarra Navy Port, making the Royal Australian Navy the latest Australian Defence service with the capability to additively manufacture its own metal parts on-demand.

Sustainment or the repair, maintenance and overhaul of equipment is said to make up a substantial proportion of the cost of all defence forces globally. The difficulty and expense of sourcing spare parts through regular supply chains has been exacerbated and highlighted by the coronavirus (COVID-19) pandemic, explains SPEE3D.

“The world has been looking to AM to solve this problem, however, most AM technology has proven too delicate, too expensive, and far too slow to solve the problem. SPEE3D has proven to be the exception,” stated the company.

According to SPEE3D, its large-format cold spray metal Additive Manufacturing technology is the only one of its kind to have been trialed and proven field-deployable by the defence sector. The company recently completed a series of successful field trials deploying the WarpSPEE3D AM machine to the remote outback with the Australian Army.

The Australian Government funded the $1.5 million trial, which included the training of army craftsmen and engineers in Additive Manufacturing at Charles Darwin University. The programme resulted in a range of parts that the army is now able to additively manufacture and finish in the field at a fraction of the cost and time of current supply chains. The pilot programme with the Royal Australian Navy is expected to produce similar results.

SPEE3D explains that the installation of a WarpSPEE3D AM machine at HMAS Coonawarra was made possible after the Australian Government invested $1.5 million in a similar eighteen-month pilot installation for the Royal Australian Navy.

Byron Kennedy, SPEE3D CEO, commented, “We are excited to be working with The Royal Australian Navy on this programme. Having the capability to produce high-quality metal parts on-demand, in the field or at sea will be ground-breaking for the Australian Defence Force.”