Wabtec establishes Additive Manufacturing centre for railway parts in the EMEA region

October 27, 2023

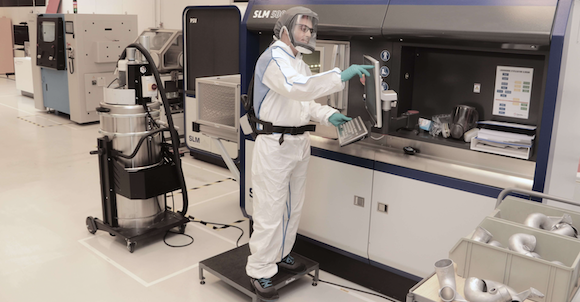

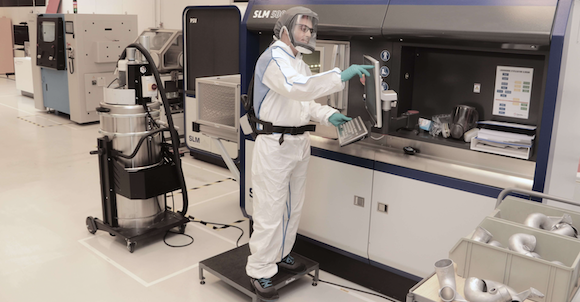

Wabtec Corporation, headquartered in Pennsylvania, USA, has established its first Additive Manufacturing centre in the EMEA region. This centre focuses on the production of additively manufactured parts for the railway industry. Nikon SLM Solutions has been chosen as the supplier of machines and technology solutions, with the inclusion of an SLM®500 Laser Beam Powder Bed Fusion (PBF-LB) machine in the centre.

The Additive Manufacturing centre, located in Tours, France, encompasses the complete AM process chain, from producing high-quality metal parts to quality control and post-processing. Wabtec states that the centre’s opening addresses obsolescence issues by enabling high-quality spare parts, produced on Nikon SLM machines, to be shipped within a few weeks after order confirmation, allowing trains to be swiftly returned to service.

Wabtec AM has been using the SLM 280 and SLM 800 machines in its US network. With the addition of the SLM 500, the company will operate nearly the entire product range of Nikon SLM machines.

Henri de Chassey, Head of Additive Manufacturing in Wabtec Transit, shared, “We have selected Nikon SLM Solutions as they were proposing the best technical option on aluminium, but also because some of our previous validated parts have been already produced on their machines. Nikon SLM’s technical team additionally has provided us and our applications an amazing support for the implementation of this new project.”

The production encompasses basic spare parts manufactured by Wabtec. These are produced primarily to address supply chain or obsolescence issues. However, new products are also created for a variety of applications such as brake systems, pantographs, HVAC, and doors.

Ralf Frohwerk, Global Head of Business Development at Nikon SLM Solutions, added, “We are excited about our partnership with Wabtec, which has already yielded many production-ready metal parts. The opening of the 3D printing centre is moving the rail industry forward. This example shows the operational feasibility of Nikon SLM technology. Serial parts produced on Nikon SLM machines are made available quickly, meet all safety-critical requirements in the industry, and enable the railway industry for new functional part design revolutions.”

The location of Tours is reported to be strategically important for Wabtec. The site comes equipped with post-processing options to finish the parts produced, from machining to painting and surface treatment if necessary. All production lines adhere to the high-quality requirements of railroad standards.

Download Metal AM magazine