WAAM3D highlighted by European Commission’s Innovation Radar

March 1, 2023

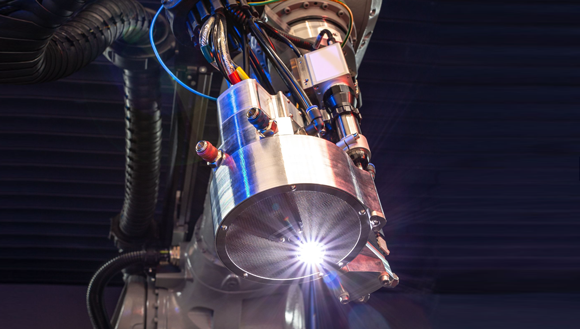

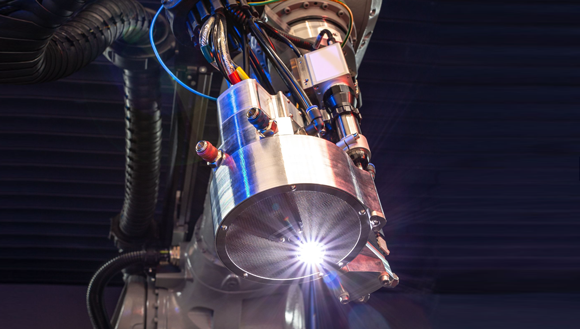

WAAM3D, Milton Keynes, UK, has been highlighted as a Key Innovator by the European Commission’s Innovation Radar. This is a result of the company’s work with Cranfield University in creating multi-material add-on software for Wire Arc Additive Manufacturing machines.

WAAM3D and Cranfield University’s joint work in multi-material add-on software for WAAM machines has been awarded ‘market ready’ status by Innovation Radar. This is because the software is deemed technologically mature and there is high commitment from the providers to bring it to market. The solution has also been acknowledged as addressing the needs of existing markets.

The Innovation Radar is part of the MULTI-FUN (Multi-Functional) project, funded by the European Commission under Horizon 2020. This programme aims to make information about EU-funded innovations from high-quality projects visible and accessible to the public via the EU’s Innovation Radar platform.

Dr Filomeno Martina, CEO and co-founder of WAAM3D, stated, “We are very pleased that our work with Cranfield University is being acknowledged in this area of WAAM. These are exciting times for WAAM, and its potential for transforming large-scale metal component 3D printing is only just beginning to be seen in real-world applications.”

Details about this innovation can be found on the European Commission’s Innovation Radar platform

Download Metal AM magazine