Velo3D qualifies copper alloy for its Sapphire AM machines

May 9, 2022

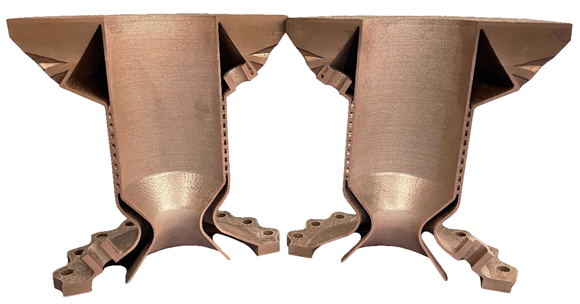

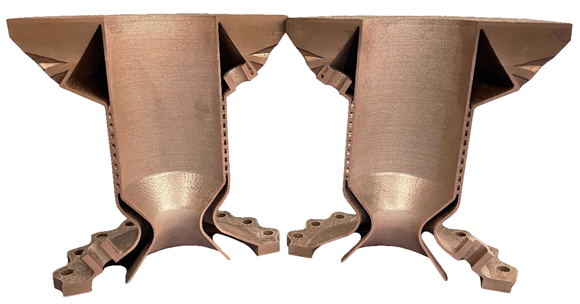

Velo3D, Campbell, California, USA, has qualified the copper-chromium-niobium alloy GRCop-42 for use in its Sapphire family of Additive Manufacturing machines. Developed by NASA to manufacture parts in need of high-strength and high-conductivity, Velo3D customers can now use the GRCop-42 alloy to produce mission-critical parts with oxidation resistance and high creep strength at temperatures as high as 760°C.

“Our end-to-end solutions have seen extensive adoption in aerospace because of their ability to deliver part consolidation, lighter-weight systems, and unique geometries, and adding GRCop-42 to our growing list of available materials enables us to support more use cases across the aerospace industry,” stated Benny Buller, Velo3D CEO and founder.

“We’ve had extensive demand for Sapphires and Sapphire XCs that can print GRCop-42 and we’ve tested it to ensure it can achieve the same high-quality builds as our other offered materials. I’m looking forward to seeing how customers unlock new use-cases for additive manufacturing with this amazing alloy,” added Buller.

GRCop-42 was developed by NASA in 1987 for use in harsh environments that are commonly found in rocket engine combustion chambers. The alloy was created after research teams identified ways to make improvements to previously-developed copper alloys. GRCop-42 stood out due to its ability to achieve higher thermal conductivity compared to its predecessor while achieving similar strength properties. In 2017, NASA developed parameters for GRCop-42’s use in Additive Manufacturing at its Marshall Space Flight Center in Alabama and Glenn Research Center in Ohio.

Velo3D contract manufacturer Knust Godwin will receive the first Sapphire AM machine utilising GRCop-42. The Texas-based company has three systems currently in place including other alloys, such as Inconel. Knust Godwin’s parent company Schoeller-Bleckmann Oilfield Equipment, which is headquartered in Austria, also has a Velo3D end-to-end solution.

“Our team is always looking for new ways to differentiate our business and because of that we were an early adopter of Additive Manufacturing technology, which has helped us grow our business and better serve our customers,” stated Mike Corliss, Knust Godwin VP of Technology. “Additive Manufacturing allows us to build parts for our customers that could not otherwise be manufactured using conventional, subtractive manufacturing. These new, powerful alloys, like GRCop-42 — that provide added capabilities and benefits for our customers — allow us to expand our addressable use-cases.”

The first GRCop-42 demonstration parts will be on display at Velo3D’s booth at RAPID +TCT, taking place in Detroit, Michigan, USA, May 17–19, 2022.

Discover more about the design and production of additively manufactured rocket propulsion systems in our article: