Velo3D announces purchase orders totalling $27 million since mid-December

April 9, 2024

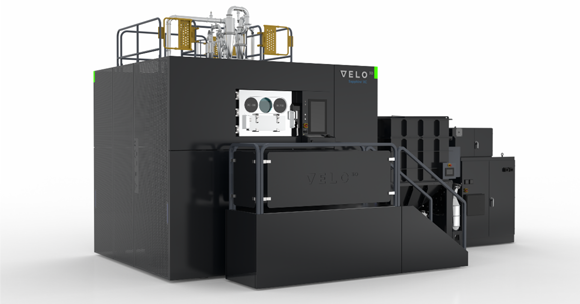

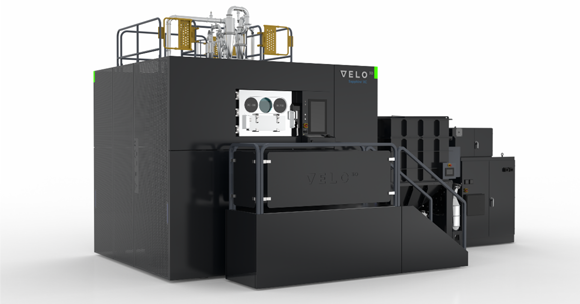

Velo3D, Inc., headquartered in Campbell, California, USA, reports it has received purchase orders totalling $27 million since mid-December 2023. These orders include the purchase of two Sapphire XC Additive Manufacturing machines by Mears Machine, a global contract manufacturer, where the machines will be dedicated to supplying parts for its defence and aerospace initiatives.

“These new orders reflect continued customer confidence in our technology and reinforces the success of our new go to market strategy, especially in the defence and space industries,” said Brad Kreger, CEO of Velo3D. “We are also very encouraged to see that our renewed focus on system reliability and customer success is yielding results as more than 50% of these orders are from existing customers. We are also pleased to welcome Mears Machine as a customer as they look to utilise our industry-leading capabilities to accelerate metal AM deployment in the aerospace and defence industries.

“Finally, I would like to reiterate that our strong bookings reflect the value of our technology, given its ability to accelerate innovation for customers, meaningfully improve lead time for mission-critical parts, and streamline the process of scaling to volume production when compared to conventional metal 3D printers,” Kreger continued.

Velo3D ended the first quarter of 2024 with bookings of $17 million and the company’s backlog at the end of the first quarter was $23 million, with machine deliveries expected to start in the second quarter of 2024.

Download Metal AM magazine