Velo3D announces large-format Sapphire XC metal Additive Manufacturing machine

October 21, 2020

Velo3D, Campbell, California, USA, has announced the Sapphire XC, a large-format metal Additive Manufacturing machine. The new machine is said to increase production throughput by five times, whilst reducing cost-per-part by up to 75%, when compared to the company’s existing Sapphire machine.

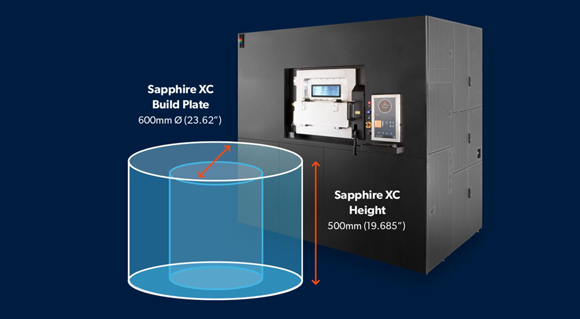

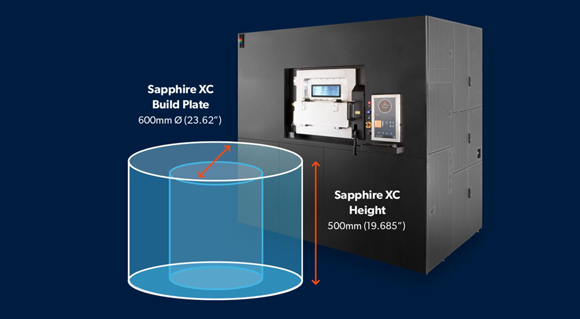

The new Sapphire XC features a build volume of 600 mm x 550 mm, compared to 315 mm x 400 mm in the Sapphire. Productivity is increased thanks to the use of eight 1,000 W lasers, compared to two 1000 W lasers in the Sapphire.

The company has also announced plans to roll-out Sapphire Gen 2, a software and hardware upgrade to the current machine. Users can expect an improvement of anywhere between 10–50% in productivity and part-cost metrics when compared to the current Sapphire system. The Sapphire Gen 2 upgrade will be available to retrofit on all installed systems starting in Q2 2021.

The Sapphire product family now includes Sapphire Gen 2, the one-metre tall Sapphire 1MZ and Sapphire XC — all using the Laser Beam Powder Bed Fusion (PBF-LB) process with patented capabilities to build without consideration of support structures. Sapphire machines are said to be targeted specifically at the aerospace, power generation and energy markets’ need for quality-assured manufacturing of uncompromised geometries.

“Printing larger parts without the Additive Manufacturing constraints of support structures is highly attractive to many industrial end-users,” stated Benny Buller, founder and CEO of Velo3D. “For the first time, customers will be able to 3D-print uncompromised geometries, with the highest confidence in part quality, in a large format system.”

“Quality assurance with large-scale components is critical because the economic impact of failed builds is very significant. We have demonstrated that our integrated solution is capable of producing a greater yield of high-quality parts, and that foundational technology will transfer to our new Sapphire XC,” he added.

Velo3D states that, to date, it has received thirteen advance orders for its new metal Additive Manufacturing system, with delivery of the Sapphire XC expected to begin in Q4 2021.