US Army lab partners with University of Central Florida to optimise AM

April 21, 2021

U.S. Army researchers have collaborated with academic partners from the University of Central Florida to make improvements in Additive Manufacturing processing, in hopes of delivering extremely lightweight components to future soldiers.

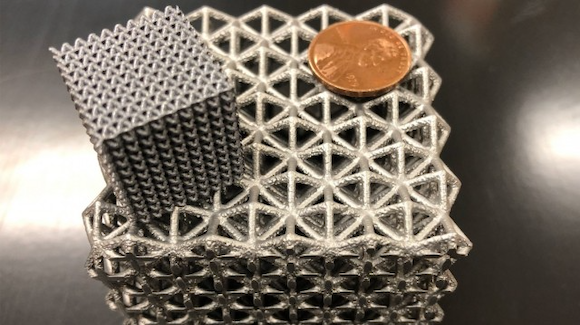

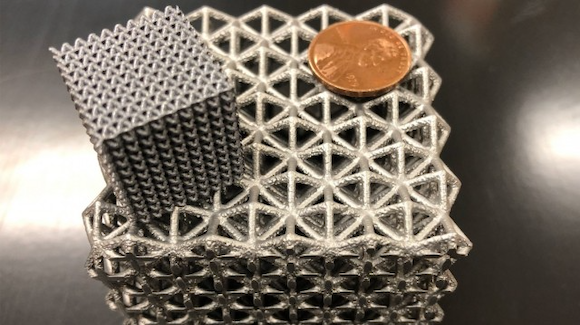

By optimising the AM process for the production of a high-strength magnesium alloy and fabricating twenty-four micro-lattice structures, researchers have characterised the compressive strength and failure modes, which will allow for lightweighted components.

“We used a magnesium alloy known as WE43, which has only been successfully 3D printed by a handful of researchers,” stated Dr Brandon McWilliams, the lead researcher for metal AM at the U.S. Army Combat Capabilities Development Command (DEVCOM) Army Research Laboratory. “In this work, we optimised the process to achieve higher density than previously reported, and used that to produce and characterise lattice structures made up of WE43.”

Magnesium Elektron WE43 is a high strength casting alloy and can be used in temperatures of up to 300°C. It has good mechanical properties coupled with excellent corrosion resistance.

Advanced AM has the ability to deliver critical parts at points of need, reducing the need for lengthy logistic chains. This alongside the U.S. Army’s modernisation strategy of lightweighting loads, has the potential to make Additive Manufacturing a key aspect of modernising the organisation’s weapons systems, according to McWilliams.

“Current systems are too heavy, which increases burden to the soldier, reduces fuel efficiency and degrades mission effectiveness,” he added. “It is my goal as an Army researcher to conduct research, which has the maximum chance of success of transition from basic and applied research stage to practical application in order to enable transformational overmatch.”

Partnering with academia and industry has been a priority with the laboratory since the introduction of its Open Campus initiative.

“This was an exciting and rewarding collaboration that produced the technological accomplishment founded on fundamental understanding of materials and Additive Manufacturing,” stated Yongho Sohn, lead researcher at the University of Central Florida. “Technological vision with clear scientific objectives defined by Dr McWilliams and his team was the key to our contribution.”

Army researchers will now evaluate the high strain rate and ballistic properties of these additively manufactured materials and look for demonstration applications, such as ultra-lightweight unmanned aircraft system and robotic vehicle components.

The research team published their current findings in the peer-reviewed journal Materialia.