Update on project to increase powder efficiency in Additive Manufacturing

January 11, 2023

TWI, Cambridge, UK, has announced an update from the UK Research and Innovation (UKRI) funded Scalable AM Rule Creation and Dissemination (SAMRCD) project, run in collaboration with Authentise, the Materials Processing Institute (MPI) and Photocentric.

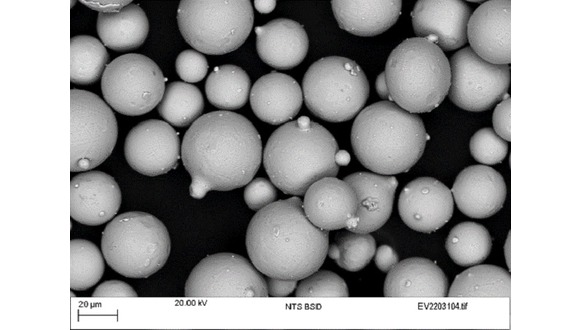

Powder characteristics can be greatly influenced by the surrounding environment, explains TWI, which ultimately affects the materials properties found in parts created via Laser Beam Powder Bed Fusion [PBF-LB]) for example. The SAMRCD project is looking into the PBF-LB Additive Manufacturing cycle, with a particular focus on powder production and properties to assess the influence of powder characteristics and storage conditions on the as-built microstructure and mechanical properties for Alloy 718 material.

To this end, plasma atomised (PA) Alloy 718 powder was fully characterised, then exposed to conditioning trials using the recently acquired Weiss environmental chamber. Preliminary results show a direct correlation between conditioning environment and hold time and powder flowability. In fact, extended conditioning time drastically impaired the powder flowability, demonstrating the importance of powder storage in guaranteeing adequate powder quality with minimal moisture content.

TWI is now working on establishing a new PBF-LB process parameter window for conditioned Alloy 718 powder. Once parameters have been established, the microstructure of as-built virgin Alloy 718 will be compared with the conditioned ones.