University of Texas rocket design project supported by EOS

January 11, 2021

EOS GmbH, headquartered in Krailling, Germany, has announced its ongoing support for the Texas Rocket Engineering Lab (TREL) at The University of Texas (UT), USA, a collegiate rocket laboratory committed to providing students with the resources and guidance to succeed in the aerospace industry. EOS is providing CAD training, professional counsel, material resources and the Additive Manufacturing of advanced rocketry components.

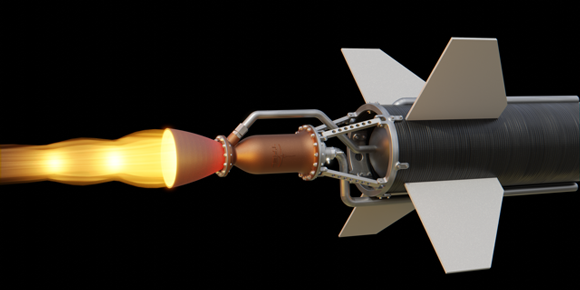

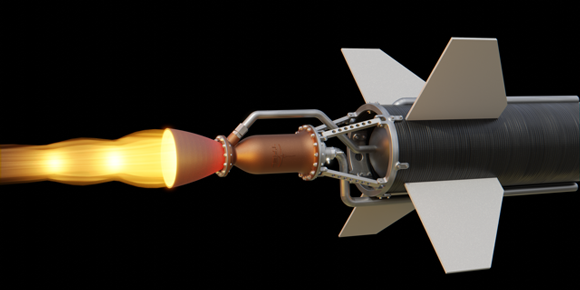

These components will be mission-critical to TREL’s Halcyon rocket project, an 8.5 m tall liquid bipropellant rocket designed to fly to the edge of space as part of the Base11 Space Challenge. The Base11 Challenge is an international competition that tasks student-led teams with launching a liquid-bipropellant, single-stage rocket to the Karman Line, an altitude of 100 km.

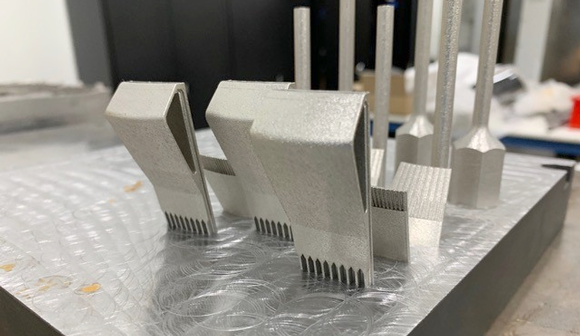

EOS will provide design and production support as the TREL students work to produce the rocket’s ‘Havoc’ engine, a regeneratively cooled, LOx–RP-1 fueled engine, that has been configured for advanced AM techniques. In addition to the Havoc engine powering the rocket, EOS will help produce aerodynamic fins to control Halcyon during flight.

“The space industry already relies heavily on 3D Printing, and today’s university students are the pipeline to advancing the industry, bringing with them both the knowledge necessary to thrive and the AM mindset to successfully engineer and create ideas never before possible,” stated Patrick Boyd, Marketing Director at EOS.

“We decided long ago to play our part in supporting TREL and similar university teams across North America, helping ensure their success and providing them direct access to our AM expertise and technology – the most direct way we can augment their studies and projects,” added Boyd.

EOS’ support has enabled TREL to undertake an ambitious design for Halcyon, as well as furthering the lab’s greater mission: to incubate the next generation of aerospace pioneers.

“Working on the EOS Havoc engine has been a highlight of my college experience,” stated Lauren Rodriguez, a third-year student at UT and lead propulsion engineer for TREL. “With EOS, I have been able to learn so much about advanced Additive Manufacturing capabilities and rocket engine fabrication, which are subjects you can’t learn in a classroom. By designing, building, and testing our own 3D prints, we are able to push forward the leading edge of rocket engine development.”