University of Birmingham adopts RenAM 500M for healthcare research

September 18, 2018

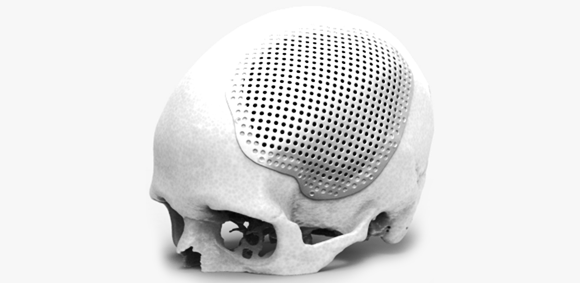

A LaserImplant cranial plate produced by Renishaw (Courtesy Renishaw plc)

As part of a new centre for custom-made medical devices, the University of Birmingham, UK, has installed two RenAM 500M metal Additive Manufacturing systems manufactured by Renishaw, Gloucestershire, UK. The systems are housed in the School of Materials and Metallurgy as part of a project to form the foundation for a healthcare partnership.

The centre is expected to bring together academia, clinical and industrial practise to speed time-to-market for medical devices and improve the options available to patients, and will reportedly bring together academics from different disciplines to explore the full potential of AM for medical devices.

The university has several active projects to innovate new medical devices and technologies to assist recovery following disease or injury, covering various clinical remits. It is currently working to develop a new generation of medical devices which are both anatomically and therapeutically customised to the patient.

One project is investigating cranioplasty, a common procedure with a high infection rate. Working alongside UK business Accentus Medical, the university is said to be looking at applying technology to the surface of customised metal AM cranial plates to reduce the chance of infections, dramatically impacting patients’ quality of life.

“Additive Manufacturing increases the design freedom for medical devices,” explained Dr Sophie Cox, Lecturer in Healthcare Technologies, Healthcare Technologies Institute, University of Birmingham. “Using the technology, we have flexibility in implant geometry and material choice. The installation of the RenAM 500M systems will create a new centre for custom medical devices at the University of Birmingham.

“We chose Renishaw because of its experience as a custom medical device manufacturer,” she added. “Renishaw has a wealth of expertise in taking medical devices to market. As a university, we are working towards ISO 13485, something Renishaw has already achieved.”

“This is a really enthusing project and we are excited about the future of the industry,” commented Bryan Austin, Director and General Manager of Medical and Dental Products at Renishaw. “Through its work with the Birmingham Health Partnership, the university has access to clinical input from local hospitals. By collaborating with industrial, academic and clinical partners, it is possible to produce medical devices more quickly and at a lower cost, which will benefit patients receiving the implants.”