Uniformity Labs releases 17-4PH stainless steel powder for Binder Jetting

September 14, 2022

Uniformity Labs, Fremont, California, USA, has announced the availability of its ultra-low porosity 17-4PH stainless steel powder for the Desktop Metal Shop System Pro binder jet machine. Developed in-house, the high-performance metal powder is said to deliver superior material properties, sintered part geometric accuracy, process yield and print uniformity with high throughput.

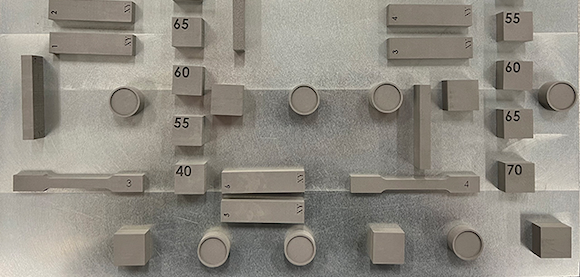

Uniformity Labs states that the 17-4 PH powder exhibits a typical tap density of 5.33 ± 0.05 g/cm3. A high – and highly repeatable – sintered density of 7.68± 0.03 g/cm3 and in-build brown density deviation of +/- 0.024 g/cm3 is said to deliver uniform sintering shrinkage across the bed. Brown density across builds, batches, and in-spec process and environmental parameters averages 4.49 +/- 0.05g/cm3, reportedly delivering at better than 95% confidence levels inclusive of batch-to-batch, spread, build, cure, de-powder, and sinter sources of variation, a highly uniform sintering shrinkage of 15.17% ± 0.65% in the X direction, 15.66% ± 0.65% in the Y direction and 18.18% ± 0.63% in the Z direction. This low and stable shrinkage allows the Binder Jetting of comparatively large parts, up to tens of centimetres in length.

The process stability is said to be enabled by the low-cohesion, low-porosity powder that repeatably spreads uniformly across the build bed. The high brown densities result in up to 50% reduction in linear shrinkage relative to competitor materials and repeatably deliver 99-100% final part density. An additional benefit of low shrinkage is increased throughput due to greater use of the build volume. The flowable powder is said to further improves throughput by allowing repeatable fast layering, with a net throughput benefit of approximately 50% relative to non-Uniformity powders on comparable platforms, thereby enabling substantial cost reduction to be taken advantage of by parts manufacturers contemplating adoption of metal Additive Manufacturing at scale.

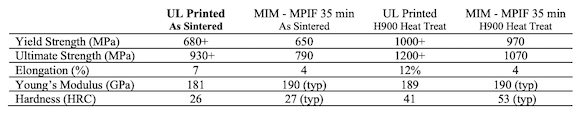

17-4 PH is martensitic precipitation hardened stainless steel, known for its corrosion resistance and high strength and hardness levels, especially when heat treated. 17-4 PH can be heat treated to various hardness and toughness levels, allowing users to customise the post-sintering properties of the alloy to suit a wide variety of applications, such as chemical processing, manufacturing machinery, and food processing.

“The application of Uniformity17-4 PH stainless steel for BJT delivers mechanical and process excellence for our customers who require materials that perform to the highest standard across each step of the production process,” stated Adam Hopkins, Uniformity founder and CEO. “Our powders deliver superior mechanical properties, surface finish, printing yield, and process stability, allowing one machine to do the work of several.”