Uniformity Labs highlights benefits of its AlSi10Mg powder and build parameters in engine component design

September 8, 2022

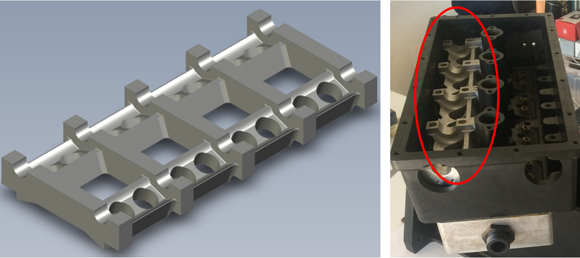

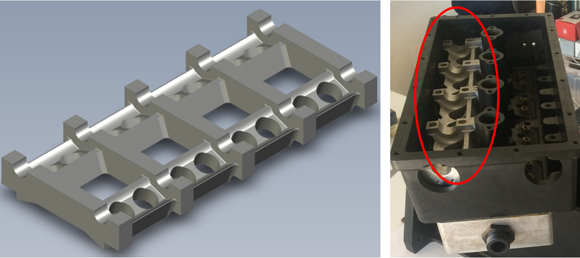

Uniformity Labs, Fremont, California, USA, has partnered with race car engine developer Polimotor, Wellington, Florida, and Incodema3D, Freeville, New York, to additively manufacture and evaluate a cam tray component for use in an engine designed by Polimotor.

Incodema3D used an EOS M290 Additive Manufacturing machine to build the cam trays. The first step was to simulate and compare build times using conventional EOS M290 AlSi10Mg powder and parameters versus Uniformity AlSi10Mg powder and Uniformity optimised parameters.

Uniformity executed build time simulations using Uniformity HPS settings at 30 μm and 50 μm to compare with EOS 30 μm and 40 μm standard settings. Incodema3D then additively manufactured two halves of the cam tray at 30 μm and 50 μm layers to validate the simulated build times.

The results showed that the actual build times were within 1% of those simulated, illustrating the accuracy of the simulations and the ability to use them as a quoting tool.

It was reported that Uniformity as-built densities were 99.9%, compared to EOS ≥99.8%. Uniformity mechanical properties at 30 μm were said to be superior to best-in-class 30 μm, and at 50 μm are comparable to best-in-class 40 μm. Uniformity also achieved less than 4 μm Ra on as-built vertical surfaces at 30 um layer thickness, with slightly higher values at 50 μm layer thickness.

It was added that at the same 30 um layers, Incodema3D demonstrated a 181% improvement in throughput versus EOS conventional powder and parameters with no compromise to material properties. At 50 um layers, Incodema3D demonstrated a 163% improvement in throughput versus EOS conventional 40 um build time without compromise to material properties, delivering an average density of 99.85%.

“This is a strategically important case study because it shows the significant advantages of using our engineered materials for advanced manufacturing of critical components for use in the transportation industry,” stated Uniformity founder and CEO Adam Hopkins. “The results show that we can achieve faster, more cost-effective part production without compromising material properties.”

Matti Holtzberg, founder, Polimotor, added, “Since we created the world’s first super light-weight polymer engine in 1980, manufacturing technologies have advanced to allow us to include 3D printed metal components along with the polymer components in the engine design. The case study we just completed on the engine cam tray, with Uniformity’s advanced aluminium alloy powder and print parameters, produced at Incodema3D, shows substantial benefits in manufacturing time, which will have a significant impact on reducing the cost to make these and other components for our engine.”

“Along with the inherent benefits 3D printing provides in reducing weight and optimising designs, the ability to reduce cost without compromise to material properties has significant implications not just for producing racing engines but for the global auto industry, which faces a growing demand for lighter, more fuel-efficient cars,” Holtzberg concluded.

The full case study is available here.