UCLA and LLNL materials scientists receive grant to develop AM lithium-ion batteries

August 3, 2022

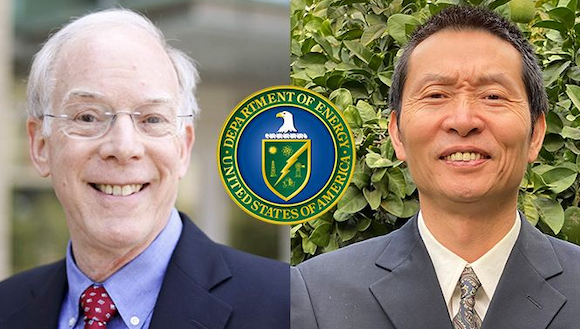

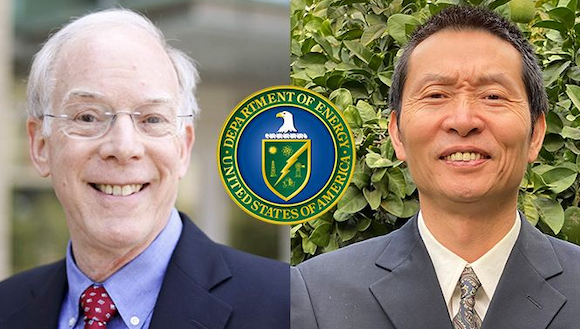

Materials scientists at the University of California, Los Angeles (UCLA) Samueli School of Engineering, led by Bruce Dunn and Morris Wang, along with colleagues at Lawrence Livermore National Laboratory (LLNL), Livermore, California, have been selected to receive a $900,000 grant from the US Department of Energy to demonstrate a new design and Additive Manufacturing process for manufacturing lithium-ion batteries.

The team’s goal is to improve lithium-ion batteries by increasing the available power, speeding up charging and making them cheaper to manufacture while wasting less material in the process. Additive Manufacturing allows for the creation of a more intricate interior battery structure that can store more power — a development thought to be critical to the new manufacturing process.

Dunn is a professor of materials science & engineering, company chair of UCLA’s Nippon Sheet Glass Company; and, as of August 1, interim dean of the engineering school. He will serve as the principal investigator of the project, which is part of a $57.9 million programme to fund research into clean energy technologies. Wang, who is also a professor of materials science and engineering, is the co-principal investigator.