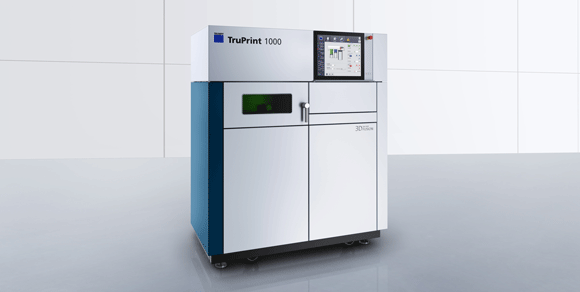

Trumpf’s TruPrint 1000 metal Additive Manufacturing system to make UK debut at TCT

September 26, 2016

Trumpf GmbH, Ditzingen, Germany, will be displaying its new compact TruPrint 1000 metal Additive Manufacturing machine for the first time in the UK at TCT Show + Personalize 2016, Birmingham, UK, September 28-29.

Designed for the production of small, complex components, this smaller laser metal fusion system is described as a true plug-and-play machine that’s easy to install and only requires 240V of power and an inert gas connection. Thanks to an innovative coating system, the company states that downtimes are reduced to a minimum.

In line with Trumpf’s previous laser metal fusion (LMF) system, the TruPrint 1000 builds components from a wide range of fine metal powders including steel, aluminium and titanium using a build space of 100 mm x 100 mm. This technology is especially suitable for parts with a complex geometry – such as those with internal channels and hollow spaces, and for economical manufacture of individual parts, prototypes or short production runs.

Proposed application areas include everything from tool and mould-making, through to dental applications for the production of crowns and dental bridges. Trumpf added that it is also seeing potential with demanding applications in the aerospace industry and turbine construction where the technology allows for weight savings of between 30 and 50% with the same, or improved, mechanical qualities.

Trumpf recently setup a dedicated department in Ditzingen to handle its continued development of its LMF technology meaning all operations are located under the same roof and headed by a team of applications engineers.