Trumpf to launch its new TruPrint 3000 metal Additive Manufacturing system at formnext

November 9, 2016

Trumpf utilises both Laser Metal Fusion and Laser Metal Deposition technology (Photo: Trumpf)

Laser manufacturer Trumpf, based in Ditzingen, Germany, has announced it will be showcasing its latest metal Additive Manufacturing systems at the formnext trade fair in Frankfurt, Germany, November 15-18, 2016. Along with its range of existing technology the company will display its new TruPrint 3000, a Laser Metal Fusion (LMF) system with a 500 watt laser capable of manufacturing components up to 400 mm in height and 300 mm in diameter.

The TruPrint 3000 works on the basis of an industrial exchangeable cylinder, which allows for parallel setup and post-processing and is said to guarantee a high level of machine availability. “With the TruPrint 3000, we are shifting the focus onto the industrialisation of Additive Manufacturing based on the whole process chain. That means that we consider not only the manufacturing technology itself, but also – and this is quite in the spirit of Industry 4.0 – the work steps that precede and follow it,” stated Peter Leibinger, Head of Trumpf Laser- und Systemtechnik GmbH.

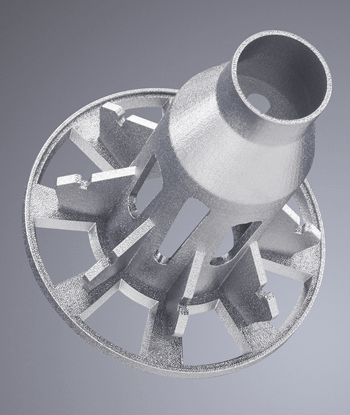

This impeller is a prototype component from the field of powerplant development. The component geometry optimises flow conditions in the engine area (Photo: Trumpf)

The process chain begins with the preparation of data for the manufacturing task, continuing on via the machine and the whole manufacturing process, including monitoring to finish with an industrial system periphery for smart parts and powder management. Trumpf states that thanks to consistently reproducible powder and part quality the TruPrint 3000 is ideally equipped for series production.

One year after the successful market launch of the TruPrint 1000, TRUMPF will also be showcasing new industrial application scenarios for this solution at formnext. The TruPrint 1000 is a compact and universally deployable LMF system that can cost effectively manufacture components of up to 100 mm in height and 100 mm in diameter.

TRUMPF utilises both Laser Metal Fusion (LMF) and Laser Metal Deposition (LMD) technology, allowing customers to select the best system to suite the manufacture of components for a variety of sectors. LMF allows the user to manufacture complete parts layer by layer in a powder bed, whereas with the LMD process the laser forms a melt pool on the surface of a component and fuses the powder – applied simultaneously and coaxially – to create the desired shape.

“Since we launched our new LMF and LMD solutions at the end of 2015, we have been seeing a significant upwards trend as well as interest from all areas of industry,” added Leibinger. “More and more customers are using additive technologies not just to manufacture prototypes, but in full-scale production as well.”

Also on show will be Trumpf’s LMD based TruLaser Cell 3000. This machine is capable of generating sandwich structures at a rate of up to 500 cm3 per hour. By drawing on LMD technology, TRUMPF is addressing not only Additive Manufacturing, but joining technology, the manufacture of coating systems, and a range of repair techniques as well.