Trumpf adds high-strength tool steel processing and green laser functionality for AM

November 22, 2018

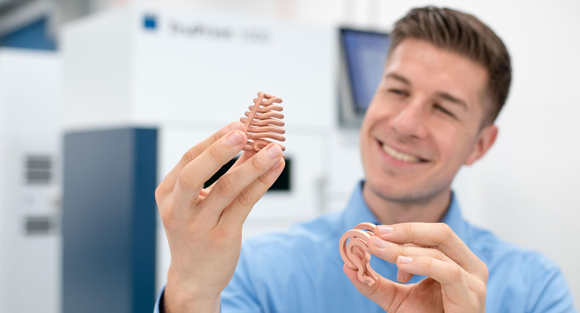

Using a green laser connected to its TruPrint 1000 metal AM machine, Trumpf has been able to additively manufacture pure copper and gold components (Courtesy Trumpf)

Trumpf, Ditzingen, Germany, has announced a range of new capabilities and highlighted new applications for its metal Additive Manufacturing technology. The company stated that its latest TruPrint 5000 machine can preheat to 500°C, allowing the production of high-strength tool steel. Trumpf also introduced a green laser option allowing the processing of pure copper and precious metals, as well as showcasing new applications in tool and mould making, medical devices and the jewellery industry.

By heating the substrate plate of the TruPrint 5000 AM system, high-carbon steels or titanium alloys can be additively manufactured without cracking or severe warping (Courtesy Trumpf)

Tool and mould makers frequently work with carbon tool steel 1.2343, an extremely hard and wear-resistant material that dissipates heat particularly well. However, this material is extremely challenging to process using Additive Manufacturing due to its propensity to crack during manufacturing.

“The laser beam melts the component surface, which subsequently cools back down to room temperature. The components weren’t able to withstand this temperature drop, and cracks formed,” explained Tobias Baur, Trumpf’s General Manager Additive Manufacturing. To address this issue, the substrate plate of the TruPrint 5000 Laser Beam Powder Bed Fusion (LB-PBF) system is preheated to 500°C, reducing the temperature drop following laser melting. “The material quality and surface of carbon steels are significantly better than without preheating, preventing fractures in the components,” he stated.

Preheating also offers advantages for titanium alloy medical prostheses and implants produced using AM, Trumpf stated. “When the ambient temperature drops too sharply, the parts warp and we have to rework them. In addition, we often require support structures that are difficult to set up and take down,” Baur added. Preheating the substrate plate is said to reduce stress, improve processing quality and, in many cases, eliminate the need for support structures. It can also reduce the need for downstream heat treatment, as well as making titanium alloys processed by AM more resilient and implants more durable as a result.

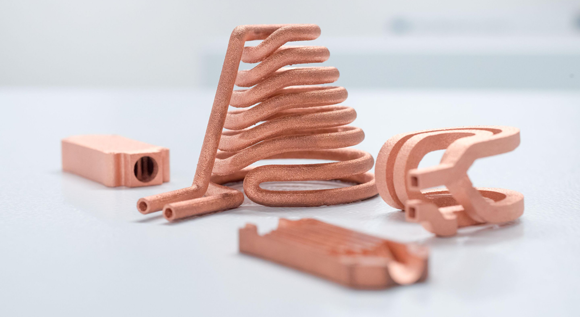

The Additive Manufacturing of pure copper has a number of potential applications in plant engineering and construction, among other industries (Courtesy Trumpf)

It was stated that using a green laser with a pulse function makes it possible to print pure copper and other precious metals. “Conventional systems use an infrared laser as the beam source, but its wavelength is too long and it can’t weld highly reflective materials such as copper and gold,” Thomas Fehn, Trumpf General Manager Additive Manufacturing, explained. “This can be done with laser light in the green wavelength spectrum.”

According to Fehn, this will open up a wider range of applications for metal AM, for example in the electronics and automotive industries. The capabilities offered by the green laser could also be especially lucrative in the jewellery industry, he added, as the AM process wastes significantly less material than conventional milling or casting processes.