Tritone DIM expands Moldjet product line

November 18, 2021

Tritone Technologies, Petach-Tikva, Israel, has announced the introduction of the Tritone® DIM, a mid-range metal AM platform. Powered by Tritone’s patented Moldjet® technology, DIM aims to address the needs of consumer goods and consumer electronics manufacturers, service bureaux, R&D and educational departments to create end-use metal parts.

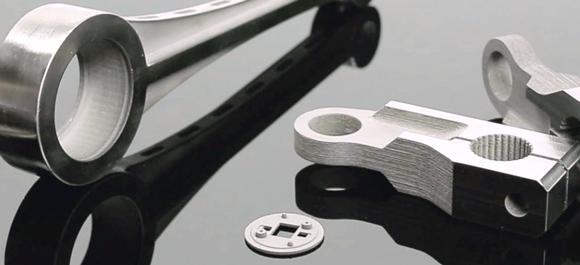

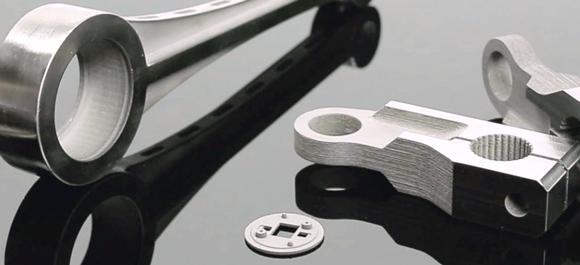

The Moldjet technology is said to facilitate the shift from prototyping to industrial production, enabling the production of a wide variety of metal and ceramic parts with fine details and high surface quality. Key advantages of the technology are said to include a reduction in lead time by up to 80%, whilst retaining the ability to produce repeatable, on-demand parts which meet demanding industrial standards.

In the first stage of the MoldJet process, a mould is produced as a negative of the component geometry from a wax-like polymer with inkjet-like print heads. This printed layer of the mould is then filled with water-based metal powder paste in a slot-die process. The process continues layer-by-layer, allowing undercuts or even internal channels to be possible without the use of support structures. Finally, the surrounding mould is removed, allowing the 3D-shaped green part to be taken for heat treatment and sintering.

“Our propriety technology is a game-changer in the AM industry,” stated Omer Sagi, VP Products and Business Development at Tritone. “Tritone’s solution can facilitate any shape, design and complexity for fast go-to-market industrial production. After the initial success of our Dominant system, we are proud to expand our market reach with the DIM system. The market is ready to shift gear from prototyping to production of high-quality metal parts, and we are proud to be at the forefront of this emerging revolution.”

Tritone is showcasing the Triton DIM together with the Dominant systems and new materials at Formnext (H1.0, E81).