Toolcraft selects Simufact Additive to simulate metal Additive Manufacturing process

September 13, 2017

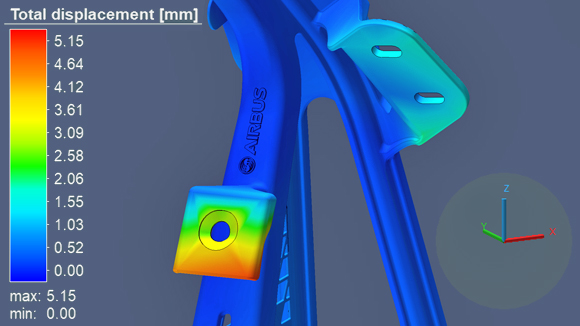

Toolcraft customers such as Airbus will profit from the use of Simufact (Courtesy toolcraft)

Toolcraft, Hamburg, Germany, has selected Simufact, Georgensgmünd, Germany to provide metal Additive Manufacturing process simulation software with the aim of optimising its manufacturing techniques. Additive Manufacturing processes will now be simulated prior to beginning the physical build process in order to move from trial-and-error to a more predictive production process, making AM more economically viable for the company.

“We have tested Simufact Additive extensively and saw that the solution is going to help us in our daily practice,” stated Christoph Hauck, Managing Director of Toolcraft. “Our clients expect us to examine the feasibility of 3D printing orders in the early project phase – the simulation of the manufacturing process is the key to this.”

“In the course of further optimisation of additively manufactured parts, simulation supplies us with fast and economical indications on how the printing process with different support structures, different orientations within the build space as well as changed machine parameters behave.”

Simufact Additive calculates distortions and residual stresses within components, shows the risk of aborted build jobs and enables users to minimise the number of physical attempts required to achieve a successful build. The software also covers post-processing simulations including heat treatment, support removal and Hot Isostatic Pressing (HIP). So far, the technology has been used primarily in the aerospace and automotive sectors.

“Simufact and Toolcraft will continue to collaborate very closely on best practices to optimise the metal Additive Manufacturing processes,” stated Michael Wohlmuth, Managing Director and CEO at Simufact. “With Toolcraft we found a partner who is an expert at the Additive Manufacturing process and shares our goal to dramatically improve the process.”