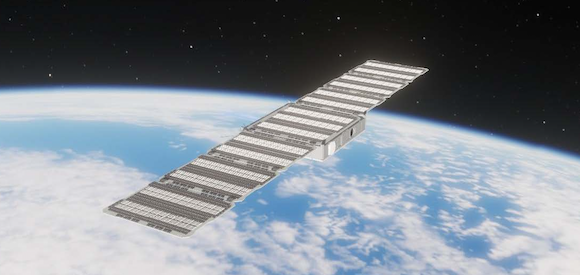

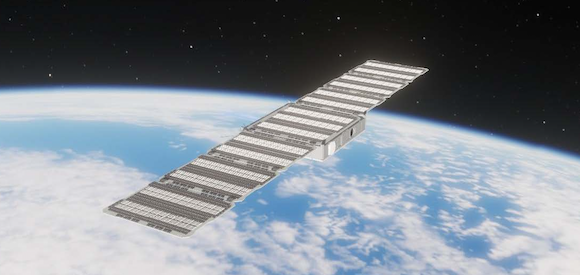

Titomic to provide radiation shielding for Fleet Space’s AM Alpha satellite

June 13, 2022

Titomic Limited, headquartered in Melbourne, Australia, has announced that it will provide radiation shielding for South Australian company Fleet Space Technologies’ first Alpha satellites, which are expected to be entirely additively manufactured. The company will use its Titomic Kinetic Fusion technology to mitigate ionising radiation, thereby prolonging the satellite’s lifespan.

The successful application of Titomic Kinetic Fusion technology for radiation shielding was accelerated by the Australian Government’s Modern Manufacturing Initiative grant. Under the grant, Titomic’s radiation shielding was tested and validated by the Australian Nuclear Science and Technology Organisation (ANSTO), after having conducted extensive simulation and physical testing at its Lucas Heights facility. The ongoing Modern Manufacturing Initiative grant activities by Titomic also include its collaboration with Boeing to create parts with ‘green’ titanium.

To provide radiation shielding, the Titomic Kinetic Fusion technology will fuse thin layers of material to produce customised, multi-material radiation shielding in a range of areal densities tailored to Alpha’s specific mission. The technology offers a cost-effective solution for shielding to protect against harsh ionising radiation in low-Earth orbit.

“Our additive manufactured multi-layer shielding is a simple and accessible solution to increase uptime and extend the useful life for a range of platforms,” stated Max Osborne, Head of Engineering, Titomic. “For example, in low-Earth orbit, a small amount of shielding provides a cost and weight-effective insurance policy for enhanced reliability and additional mission life, and for higher orbits, further shielding can even reduce a dependence on expensive, radiation-hardened components.”

“With an ever-increasing number of participants and commercialisation of space, increasing operational life is one aspect of managing congestion,” Osborne continued. “Extending the operational lifetime reduces the number of replacement platforms, their associated launch costs, and the need to track and de-orbit as many decommissioned platforms. “The successful launch and operation of the satellite will pave the way toward greater inclusion of Fleet Space and Titomic within the international space industry.”

Dr Rob Acres, Commercial Technical Consultant to ANSTO, added, “ANSTO’s involvement in this project ensured Titomic was able to turnaround design quickly, and deliver new capabilities to the sector through ANSTO’s nuclear science and technology expertise.”

Fleet Space Technologies’ Alpha satellites are expected to be launched into low-Earth orbit by SpaceX in 2023.