Titomic signs AU$25.5 million equipment sales agreement with defence manufacturer

February 25, 2020

Titomic, Melbourne, Australia, has entered into a binding contract with global defence supplier Composite Technology to provide two metal Additive Manufacturing machines. In what is Australia’s largest defence deal in metal AM, Titomic will provide two Titomic Kinetic Fusion® (TKF) Manufacturing Systems for AU$25.5 million, as part of the Australian Government’s AU$200 billion investment to build a resilient sovereign industrial capability for Australia.

Prior to signing the agreement, Composite Technology required two years of extensive research and prototyping by Titomic to guarantee the fulfilment of quality assurance requirements for the design, development and production capability of the TKF manufacturing system. With this research and prototyping complete, the sales contract for TKF Manufacturing Systems and certification for Titomic Kinetic Fusion® are expected to open up further large revenue opportunities with strong industry partnerships in high-margin industries, such as defence.

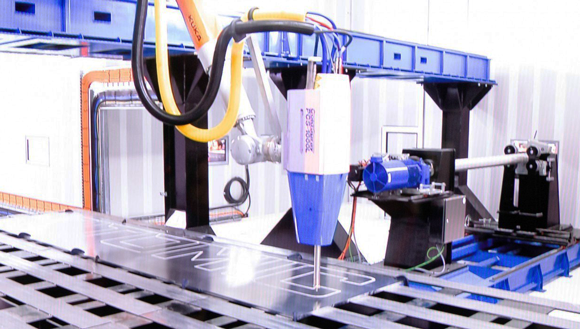

In the Titomic Kinetic Fusion® process, a Cold Spray Additive Manufacturing technology, metal powders are accelerated to supersonic speeds using an automated robotic process to additively manufacture parts. As these particles collide, a solid-state metallurgical bond is created to rapidly build large metal parts without the need for melting.

The TKF Manufacturing Systems to be delivered to Composite Technology are capable of achieving a build rate of 75 kg of metal per hour, compared to a maximum build rate of 1 kg per hour on most AM machines, reports Titomic. As a result, the company believes that its Titomic Kinetic Fusion technology is “changing the landscape of metal Additive Manufacturing”, by enabling industrial-scale serial production in direct competition with traditional manufacturing while unlocking unique material manufacturing capabilities, including the fusion of dissimilar metals and economical use of exotic metals, such as titanium.

In addition to the equipment sales agreement, Titomic reported that it recently completed a capital raise, raising AU$19 million through existing and strategic partners, and up to an additional AU$1 million through a share purchase plan for existing holders. The newly raised capital is expected to allow Titomic to expand its operations and further pursue large, high-value revenue opportunities in the aerospace and defence industries.

Commenting on the agreement, Jeff Lang, Managing Director of Titomic, stated, “I’m exceptionally excited to announce this first major revenue deal with Composite Technology, less than two years after commissioning our TKF Melbourne Bureau; a major achievement. This year, 2020, will be a major year for Titomic’s commercial development, with a focus on sales revenue and to continue along our strategic trajectory to become a major player in global metal manufacturing.”