Titomic partners with Thales to develop next-generation soldier components for Australian Defence Force

February 10, 2020

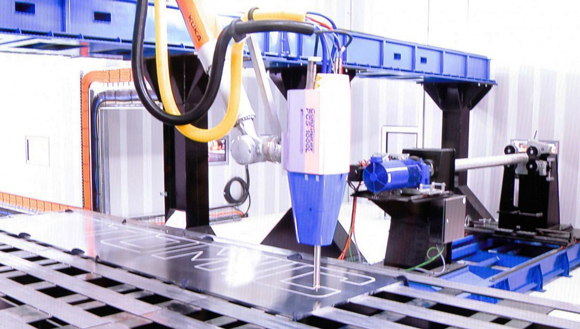

Titomic Limited, Melbourne, Australia, has signed an agreement with global technology company Thales, headquartered in Sydney, Australia, to develop advanced Additive Manufacturing methods to support Thales’s development of next-generation soldier weapons systems for the Australian Defence Force.

The company states that as part of the agreement, it will use its Titomic Kinetic Fusion® (TKF) AM process to manufacture lighter, stronger and better-performing soldier system components. That Titomic’s extensive R&D for soldier systems is now being commercialised with defence primes such as Thales is thought to validate the unique capabilities of TKF and the potential value chain of titanium from Australian resources. The company added thatt its vision is in line with the Australian government, which aims for the country to be one of the top ten defence exporters globally.

“We are proud to be partnering with Thales, a global technology leader, in the critical design and manufacture of military products for Australian and UK Defence Forces,” stated Jeff Lang, Titomic’s Managing Director. “This next generation of soldier system products will ensure our armed forces have the latest cutting-edge equipment that is lighter, stronger and higher performing, enabling them to deliver mission success in demanding and dangerous environments.”

Graham Evenden, Director of Soldier Weapons Systems, Thales, commented, “Partnering with Titomic to industrialise research outcomes in the development and manufacture of lighter and stronger soldier systems equipment continues to demonstrate Thales’s commitment to deliver capability advantage to the Australian soldier. While developing a resilient Australian Sovereign Industrial Capability that will pave the way for future export opportunities.”

The Hon Melissa Price MP, Australia’s Minister for Defence Industry, reported, “It’s great to see Australian businesses like Titomic making the most of the opportunities created through our record investment in the defence industry. It proves we are developing world-leading capability right here in Australia – which has tremendous export potential in global markets.”