Titomic to commercialise faster titanium Additive Manufacturing process

September 14, 2017

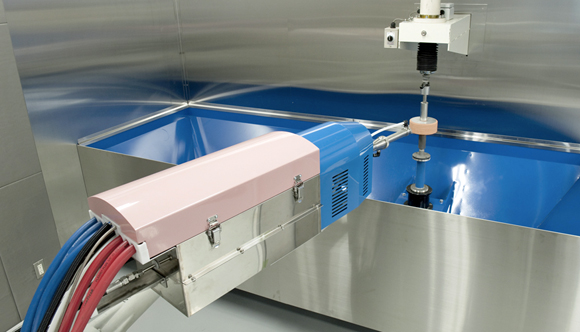

The TKF process applies titanium and titanium alloy powders onto a scaffold surface to rapidly produce titanium or titanium/composite products and parts (Courtesy Titomic)

Titomic Ltd, Melbourne, Australia, is commercialising a process capable of additively manufacturing large scale titanium parts that it claims will be thirty times faster than other metal Additive Manufacturing processes. The new technology, which it calls Titomic Kinetic Fusion (TKF), was jointly developed by Commonwealth Scientific and Industrial Research Organisation (CSIRO) and Force Industries.

The TKF process applies titanium and titanium alloy powders onto a scaffold surface to rapidly produce titanium or titanium/composite products and parts. Due to the nature of the process, powder particles do not need to be of a uniform micron size, as is required in alternative AM techniques. Titomic states that the cost of this powder is approximately 1/5 to 1/10th that of traditional AM powders, resulting in components up to 50% cheaper.

Jeffrey Lang, Titomic CEO and CTO, told The Australian, “This has been used as a coating technology but we are turning it into an Additive Manufacturing process, so instead of just coating a surface we actually build a part.”

A new facility is scheduled to open in December 2017, with trials beginning in the first quarter of 2018. The site in Melbourne will house a TKF system with a 40.5 m3 build area, reportedly making it the largest Additive Manufacturing machine in the world. “The facility we are building at the moment will have a metal 3D printer that’s 9m x 3m x 1.5m, so we are talking about Additive Manufacturing on a scale that no one can comprehend at this stage,” added Lang.