SWISSto12 and Thales collaborate on additively manufactured Active Electronically Steerable Antennas

November 22, 2023

SWISSto12, a provider of additively manufactured antenna and radio frequency (RF) system products based in Renens, Switzerland, reports it is developing Active Electronically Steerable Antennas (AESAs) for airborne, land, and maritime platforms, in collaboration with Thales, France.

An Active Electronically Steerable Antenna is an array of antenna elements that can electronically steer towards any point in various directions, without physically moving the antenna. AESAs can produce beams that are scanned at large elevation angles. This feature allows for the creation of flat arrays that can be easily incorporated into ships, land vehicles, or aircraft.

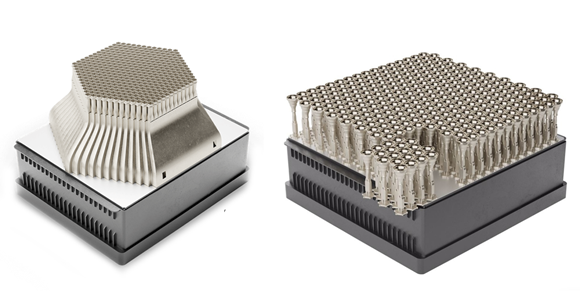

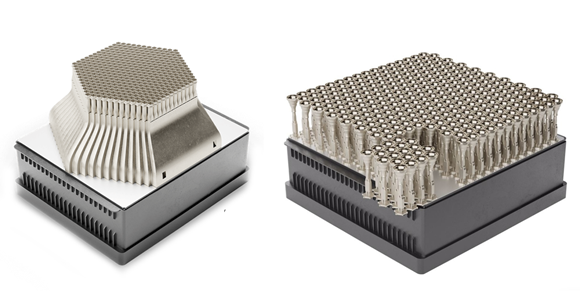

SWISSto12’s AESAs will utilise additively manufactured miniature horn antennas as an alternative to traditional patch antennas. These AM antenna apertures offer higher efficiency and superior overall performance, including gain, axial ratio and bandwidth over scan volume, compared to patch antennas. These characteristics are crucial for preserving wide-angle scanning capabilities in AESAs.

SWISSto12’s additively manufactured antennas are mounted on planar beamformers supplied by Thales. These beamformers are reported to use the latest Beamforming Integrated Circuits (BFICs) and innovative patented interconnection solutions.

Under the collaboration, Thales will leverage its legacy in designing complex layouts of microwave amplification functions, dedicated to spatial combination using the most advanced ultra-fine pitch packaging solutions available in the market.

The new AESA product will leverage improvements in Size, Weight and Power consumption (SWaP) starting with Ka band satellite communications and future combined operation across Ku and Ka bands combined in one antenna.

Emile de Rijk, CEO of SWISSto12 stated, “We are delighted to announce this new AESA product at SWISSto12, and the associated collaboration with Thales. This new class of AESAs uses our unique 3D printed antenna technology and will offer a breakthrough for users of on-the-move satellite communications across airborne, naval and land platforms.”

Charles-Antoine Goffin, Vice President, Microwave & Imaging Sub-Systems, Thales shared, “Thanks to this collaboration with SWISSto12, Thales is able to expand its RF power amplification and beamforming product portfolio. The result of this collaborative effort will be a new solution for Satcom on-the-move applications, where Thales will bring its skills on Design for Manufacturing and Design to Cost applied to electronic assemblies for competitive serial production planned in its premises. These compact AESAs will give the opportunity to SWISSto12 and Thales to serve various markets starting with commercial airborne connectivity and government satellite communications.”

In January 2023, SWISSto12 and Thales entered a contract to develop solid-state power amplifiers (SSPAs) for Space applications, specifically for SWISSto12’s HummingSat missions.

Download Metal AM magazine