SWISSto12 and Elbit Systems partner on Additive Manufacturing of advanced antennas

July 30, 2021

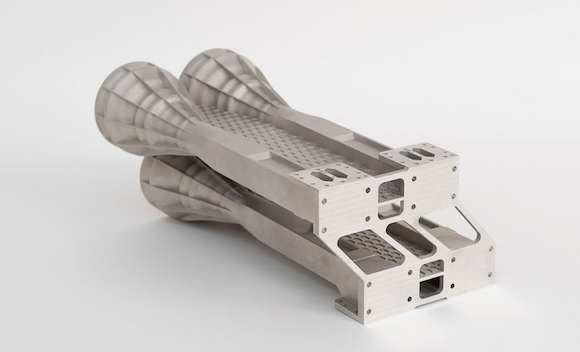

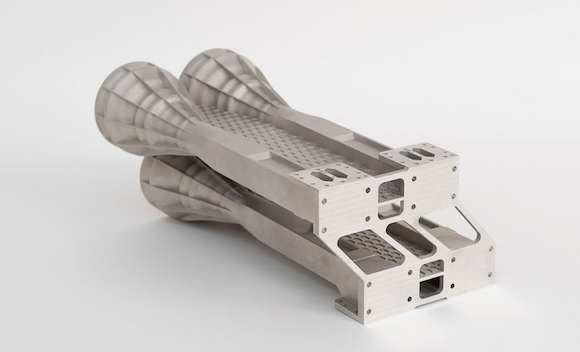

Defence electronics company Elbit Systems, Haifa, Israel, and SWISSto12, Renens, Switzerland, have partnered on the development and production of metal additively manufactured RF antennas and subsystems for Elbit Systems’ Naval EW programmes in several countries.

Elbit Systems has been selected by numerous countries to provide advanced electronic warfare (EW) solutions, including the US, Canada, Germany, and Portugal. The company believes the adoption of SWISSto12’s AM technology will ensure high-performance, cost-effective solutions.

“We feel very fortunate to partner with SWISSto12,” stated Jakob Baumann, chairman of the board of Elbit Switzerland. “Their innovative and forward-thinking approach is a perfect fit for Elbit Systems. We are convinced that we will be able to implement many successful projects together.”

Dr Emile de Rijk, founder and CEO of SWISSto12, commented, “Elbit’s well-known ambition to find new innovative solutions is a perfect fit with SWISSto12’s unique technology and product portfolio. We are truly honoured to become Elbit’s strategic partner for RF systems made by 3D printing. This strategic partnership allows us to scale our production and business volume to the next level and comes as an additional customer-focused success story.”