Swissto12 and CSEM collaborate to transform the manufacturing of radio frequency systems

January 11, 2021

Swissto12, Renens, Switzerland, and CSEM, headquartered in Neuchâtel, Switzerland, have reported on their collaborative work to transform the manufacturing of radio frequency systems for aerospace applications.

With growing demands for instant communication and massive flows of information running across the globe, data transmission needs are high and diverse. To meet those needs, today’s antennas are becoming more complex, sometimes comprised of hundreds of intricated parts. This complexity increases both the cost and the weight of such antennas, the latter being critical for antennas used in satellites.

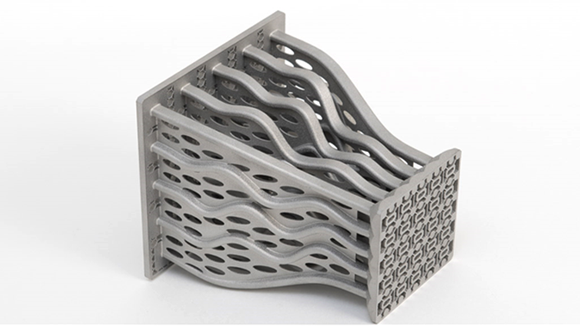

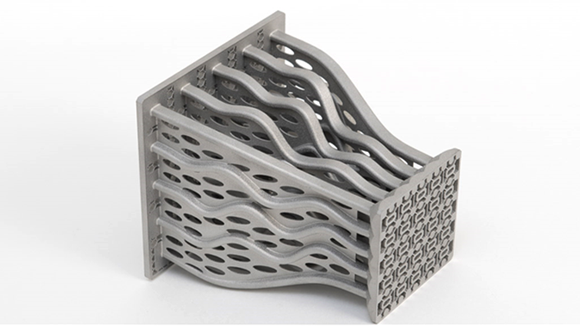

Swissto12 uses Additive Manufacturing as an alternative, customised production method, offering complex parts built as single and monolithic elements, reducing assembly time; complexity; and cost. Adapted metallisation transforms those AM parts into high-performance antennas. However, it is necessary to adapt the metallisation process to the challenges created by the novel materials and surfaces obtained by Additive Manufacturing.

The two companies have been collaborating for over four years to develop metal plating processes adapted to additively manufactured parts.

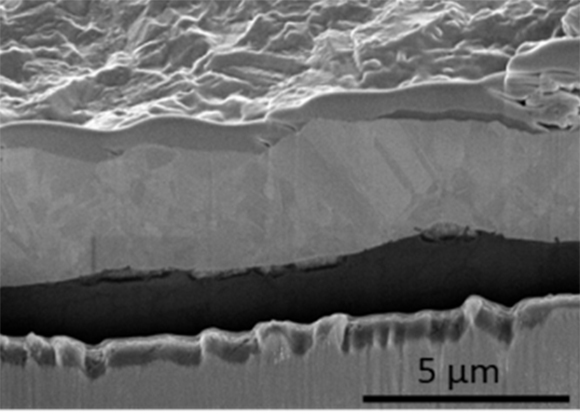

With expertise in surface engineering and chemistry, new proprietary surface treatments and electroless processes have been developed to produce highly-adhesive, conformal coatings on additively manufactured polymeric or metallic materials. CSEM is currently developing a customised electroless silver plating process enabling conformal coatings of AM surfaces to up to 10 µm thickness.