Surgeons complete eye socket repair using metal AM and augmented reality

January 5, 2021

Surgeons at Galilee Medical Center’s Center for Oral and Maxillofacial Surgery, Israel, have successfully performed an innovative surgical procedure combining Augmented Reality (AR) technology and metal Additive Manufacturing to repair a patient’s eye socket.

According to the Jerusalem Post, the surgery was carried out by Professor Samer Srouji in partnership with doctors from Sheba Medical Center. The patient was a thirty-one-year-old man who had received a severe injury, fracturing his left eye socket and causing him to experience double vision and a loss of facial symmetry.

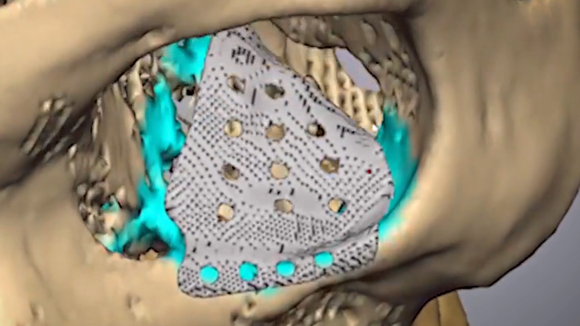

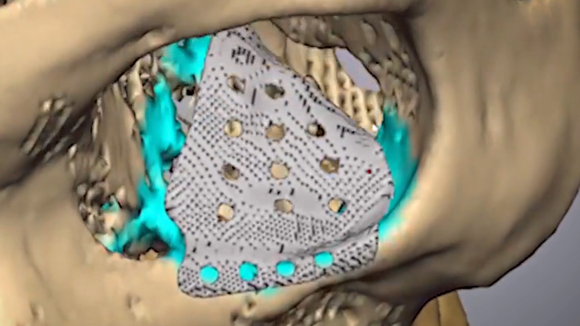

To repair the eye socket, the medical centre designed a titanium plate based on the patient’s Computed Tomography (CT) scan, accurately reproducing the shape of the floor of the eye socket by generating a three-dimensional model of the patient’s skull and basing the shape on the other, uninjured eye socket. When the design was complete, the plate was produced using metal Additive Manufacturing.

During the operation to repair the eye socket, the lead surgeon wore Microsoft HoloLens AR glasses, which connected to the computer software containing models of the patient’s skull and the AM titanium plate design. This enabled the doctor to virtually and accurately place the model over the patient’s head, enabling him to fit the plate in place more easily.

The eye surgery took just an hour and a half. Following the patient’s successful recovery and discharge from the medical centre, Prof Srouji stated, “The innovative technology utilising a 3D printer and augmented reality resulted in both a particularly accurate execution of the operation, and a significant reduction in time.”