Study explores development of meta-crystals by Additive Manufacturing

January 17, 2019

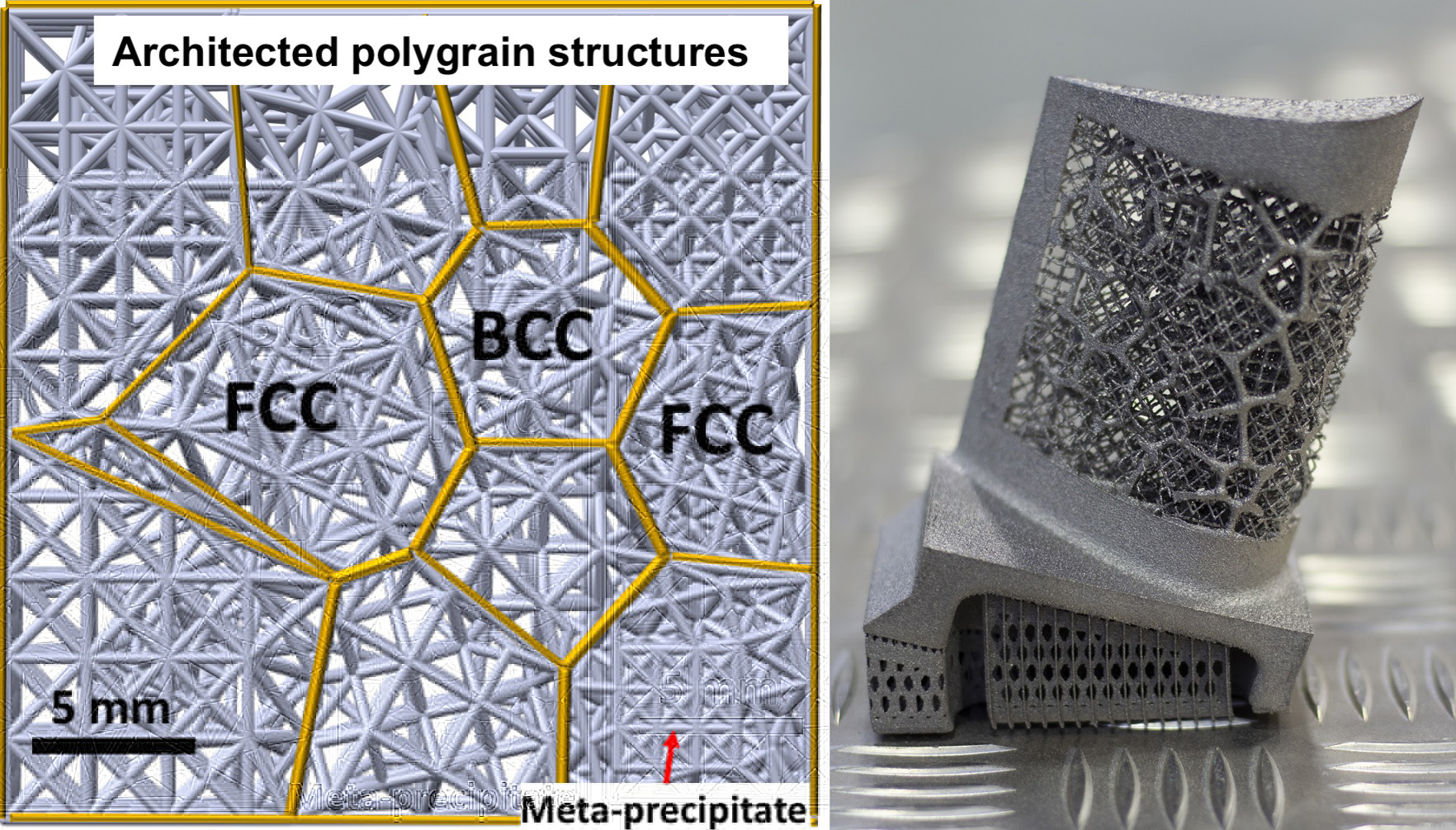

Schematic of polygrain structures (left), and a demonstration artefact showing varying orientations of meso-structures (right) (Courtesy University of Sheffield)

The Department of Materials Science and Engineering at the University of Sheffield, South Yorkshire, UK, in collaboration with Imperial College London, is investigating ways in which the use of lattice structures to replace solid materials in metal Additive Manufacturing can replicate the structure of a metallic single crystal, and the limitations this structure can impose on part performance.

Professor Iain Todd, Professor of Metallurgy at the University of Sheffield, reports that the lattice structures used in AM typically have a uniform layout, with nodes all conforming to a regular array with the struts between the nodes all following common planes: and herein lies the problem. In the study published in Nature magazine in January 2019, he states that the nodes in the AM lattice are equivalent to the atoms in the single crystal and the struts equivalent to the atomic bonds. In each of these structures, the atomic planes, or nodes, are perfectly aligned.

While in some applications, such as the high temperature end of a jet engine, single crystal materials are ideal because of their ability to withstand deformation at extreme temperatures, the structures have limitations relating to their mechanical performance. This limitation is also observed in AM parts with a uniform lattice structure: when the structure is put into compression, once the force is sufficient to cause permanent deformation, the lattice shears along one or more of the planes of nodes. With nothing to inhibit this shearing, the collapse becomes catastrophic.

In polycrystalline materials – those with many crystals – the alignment of the atomic planes is random, so when a shear force is applied in a particular direction, a crack will slow down or stop when it meets a crystal where the atoms are aligned differently from the crystal in which the crack initiated. Moreover, it is possible to introduce different materials in the form of phases, precipitates or inclusions used to strengthen the materials; these materials can also help to inhibit crack propagation.

This fundamental metallurgical understanding has inspired scientists at the University of Sheffield and Imperial College London and to mimic polycrystalline microstructures instead of single crystal structures in AM lattices, with the aim of developing robust, damage-tolerant architected materials.

Through the computer modelling of atomic structures, which are then scaled up to create meso-structures based on polycrystalline materials, the engineers believe they could transform the way that materials are designed, and have coined the name ‘meta-crystals’ for this new method.

Experimental testing of components made from these meta-crystals has reportedly demonstrated that they are highly energy absorbant, with the polycrystal-like material able to withstand almost seven times the energy before failure than the materials that mimic the single-crystal structure. While basic metallurgical concepts are being used to inspire the development of architected materials, researchers are using the creation of architected materials as an alternative approach to study complex metallurgical phenomena.

“This approach to materials development has potentially far-reaching implications for the Additive Manufacturing sector,” stated Prof Todd. “The fusion of physical metallurgy with architected meta-materials will allow engineers to create damage-tolerant architected materials with desired strength and toughness, while also improving the performance of architected materials in response to external loads. And while these materials can be used as standalone structures, they can also be infiltrated with other materials in order to create composites for a wide variety of applications.”

Dr Minh-Son Pham, Imperial College London, added, “This meta-crystal approach could be combined with recent advances in multi-material 3D printing to open up a new frontier of research in developing new advanced materials that are lightweight and mechanically robust, with the potential to advance future low carbon technologies.”